Following on from this RPM gauge thread http://www.mig-welding.co.uk/forum/threads/diy-rpm-dro.55718/ and this lathe thread http://www.mig-welding.co.uk/forum/threads/long-term-atlas-10f-lathe-restoration-modification.53210 I have started working a little bit on an electronic lead screw project.

The ELS will replace all change gears on the lathe (handy, as I have none), and it will be able to move the carriage accurately for turning, threading, and boring operations. It will also provide an RPM and Z read outs.

The plan is to make the interface as simple as possible, so that I don't have to have a computer etc out in the shed. I'm thinking something with a couple of buttons on the front to set feed rates, "stops" and jogging of the axis.

All the source code is available here: https://github.com/hbilar/arduino-electronic-lead-screw

It's very much work in progress still.

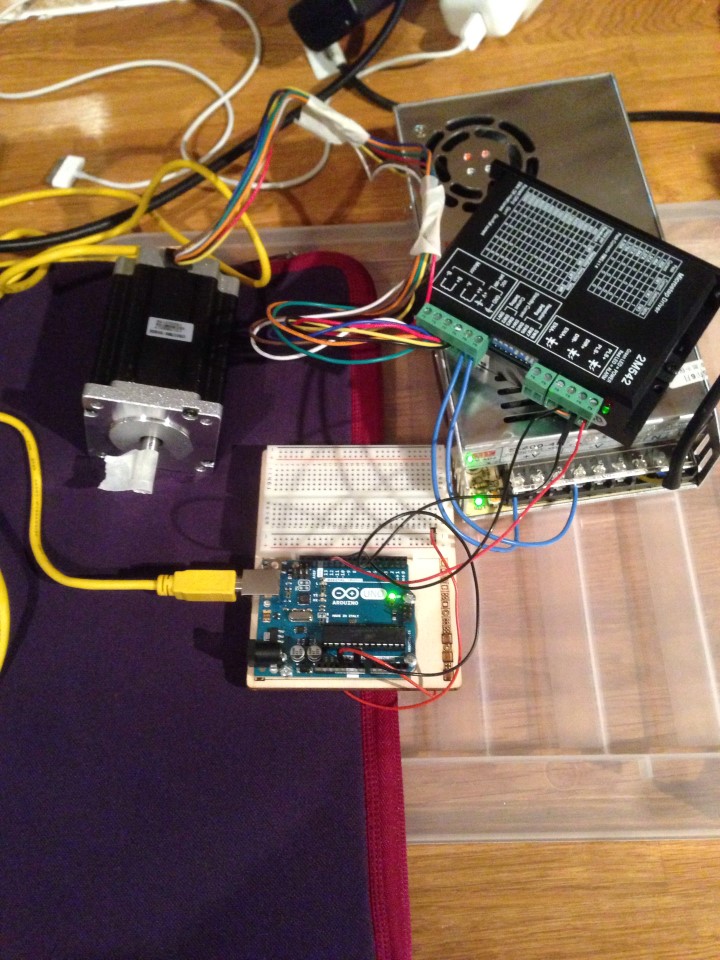

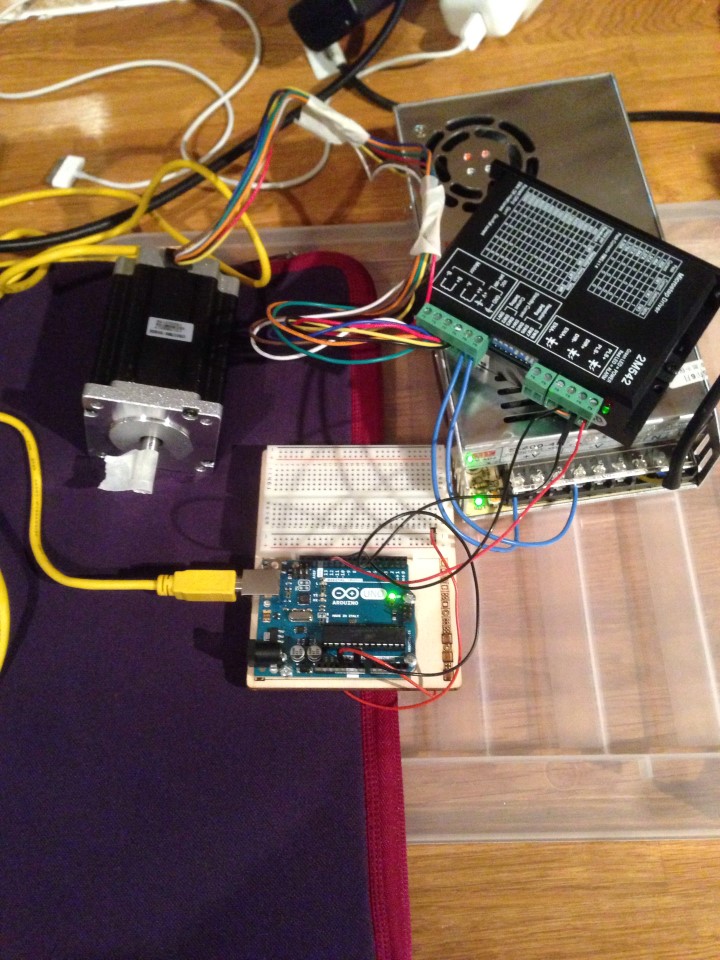

Anyway, here's a pic of the setup:

The interface is currently just a 9600bps serial interface, which you can see in the video below.

The ELS will replace all change gears on the lathe (handy, as I have none), and it will be able to move the carriage accurately for turning, threading, and boring operations. It will also provide an RPM and Z read outs.

The plan is to make the interface as simple as possible, so that I don't have to have a computer etc out in the shed. I'm thinking something with a couple of buttons on the front to set feed rates, "stops" and jogging of the axis.

All the source code is available here: https://github.com/hbilar/arduino-electronic-lead-screw

It's very much work in progress still.

Anyway, here's a pic of the setup:

The interface is currently just a 9600bps serial interface, which you can see in the video below.