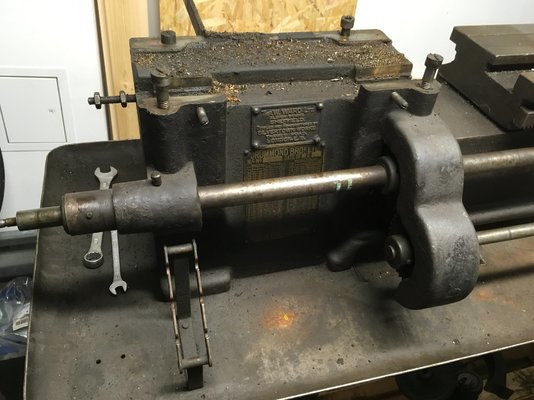

As some of you are away I picked up a fairly sizeable Drummond lathe a week or so ago. I had a spare hour last night to headed out to start the strip down, mainly to get some more weight off of it to make lifting off the trailer a little easier.

Managed to remove the headstock and some miscellaneous items, oh and grabbed a couple of photos while I was there.

I’ve got a 2 tonne engine crane coming over the weekend so all being well I’ll at least have it off the trailer and on the ground. Going to cobble together a dolly to move it around temporarily until I’ve the time to get material to make up a more permanent stand for it.

From the photo you’ll see a second plaque above the original Drummond noting Thos W Ward Ltd, Sheffield. Supplied and reconditioned by Silvertown works. So it appears it may spent some time at the ship breakers. Anybody got any more info on the Ward Company or Silvertown Works?

Updates to follow...

Edit: is there such a thing as a lathe restoration guide? Example of how things come apart etc? Will probably save a lot of head scratching!

Managed to remove the headstock and some miscellaneous items, oh and grabbed a couple of photos while I was there.

I’ve got a 2 tonne engine crane coming over the weekend so all being well I’ll at least have it off the trailer and on the ground. Going to cobble together a dolly to move it around temporarily until I’ve the time to get material to make up a more permanent stand for it.

From the photo you’ll see a second plaque above the original Drummond noting Thos W Ward Ltd, Sheffield. Supplied and reconditioned by Silvertown works. So it appears it may spent some time at the ship breakers. Anybody got any more info on the Ward Company or Silvertown Works?

Updates to follow...

Edit: is there such a thing as a lathe restoration guide? Example of how things come apart etc? Will probably save a lot of head scratching!