simon718

needs to stay off ebay

- Messages

- 2,014

...if anybody was wondering

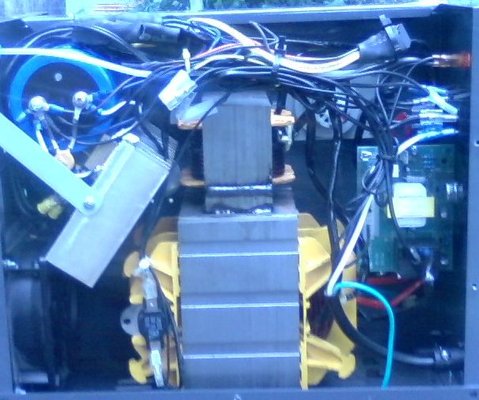

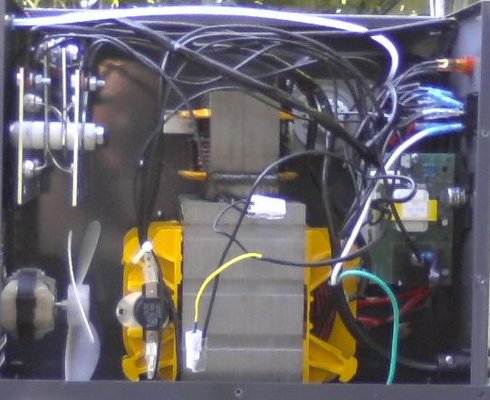

not exactly the most sophisticated machine in the world, and a lack of smoothing caps... and that fan is absolutley pathetic, next week's task is to source something a little bit more substantial, hopefully make it run a bit longer before cutting out

not exactly the most sophisticated machine in the world, and a lack of smoothing caps... and that fan is absolutley pathetic, next week's task is to source something a little bit more substantial, hopefully make it run a bit longer before cutting out

.........

.........

what all mods have you done to it??

what all mods have you done to it??

and the proper welder i want/intend on getting (lorch inverter) is over £500 so a few quid spent on mods to the cheap welder gives an improvement in the short term till i can afford better

and the proper welder i want/intend on getting (lorch inverter) is over £500 so a few quid spent on mods to the cheap welder gives an improvement in the short term till i can afford better