Hi all,

I'm in the process of building a hydraulic log splitter. I thought I'd share my progress with you all.

I'll power it off the trailer tipping pipe on my IH 434. I've got a JCB 3C Leg to build the log splitter around. I've also got a double acting spool valve with built in pressure relief valve to control it.

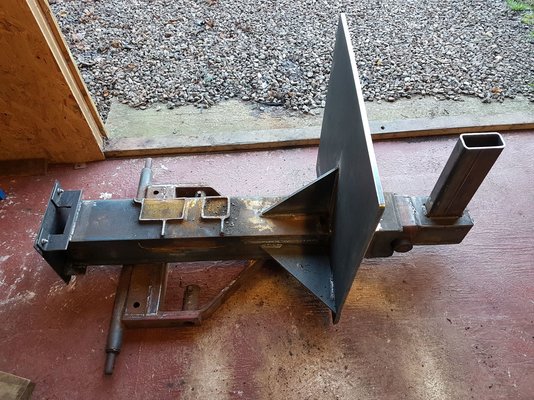

Here's the JCB leg I started with. The first thing I'll need to do is cut off all the old box and the foot. Then I'll need to get some hose's made up and check it works okay off the tractor hydraulics. Once that's confirmed I'll flip the leg upside down and weld an extension onto the smaller piece of box section, to that I will weld a splitting head. I'll then mount a table to the larger piece of box section and have the splitter doing all the work on the return stroke. I'll need to build a 3 point linkage and put a base on it so it stands up on its own when its not on the tractor.

Cheers,

I'm in the process of building a hydraulic log splitter. I thought I'd share my progress with you all.

I'll power it off the trailer tipping pipe on my IH 434. I've got a JCB 3C Leg to build the log splitter around. I've also got a double acting spool valve with built in pressure relief valve to control it.

Here's the JCB leg I started with. The first thing I'll need to do is cut off all the old box and the foot. Then I'll need to get some hose's made up and check it works okay off the tractor hydraulics. Once that's confirmed I'll flip the leg upside down and weld an extension onto the smaller piece of box section, to that I will weld a splitting head. I'll then mount a table to the larger piece of box section and have the splitter doing all the work on the return stroke. I'll need to build a 3 point linkage and put a base on it so it stands up on its own when its not on the tractor.

Cheers,

all positive so far.

all positive so far.