Kram

Member

- Messages

- 6,214

- Location

- Sussex

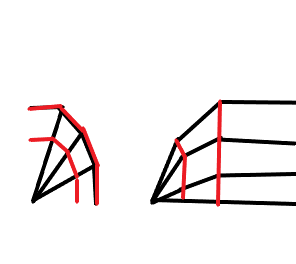

To fill the hole in my lathe chip guard. Its about a third or half of a 300mm sphere/dome shape to have clearance for the motor. I did make a cardboard mockup last year but it has not survived.

Basic tools, welder/hammer/etc. I think the dome part will need to be bolted onto the guard rather than welding to it, it needs some contorting to get back under the shelf.

Basic tools, welder/hammer/etc. I think the dome part will need to be bolted onto the guard rather than welding to it, it needs some contorting to get back under the shelf.

what about an old steel saucepan?

what about an old steel saucepan?