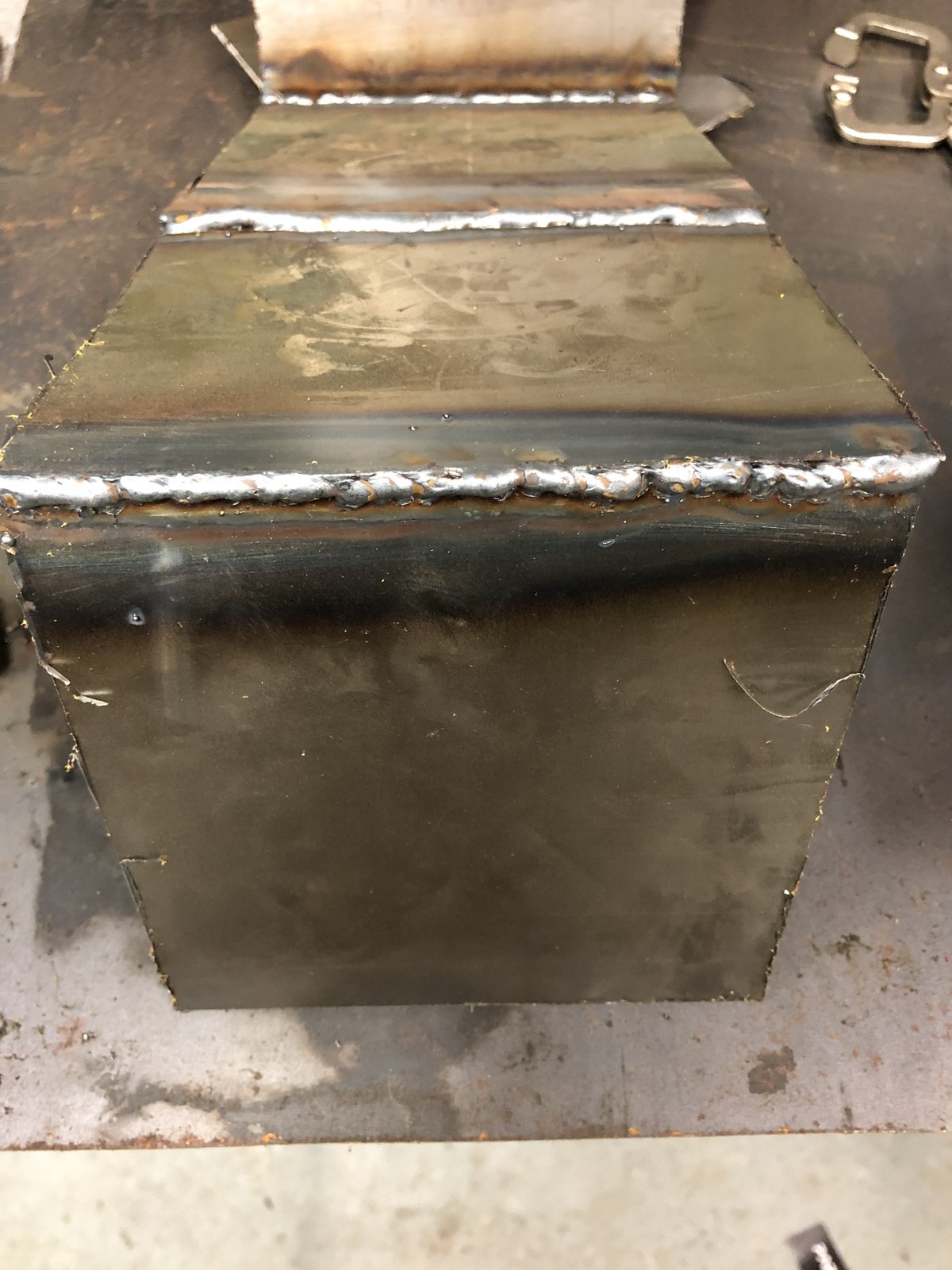

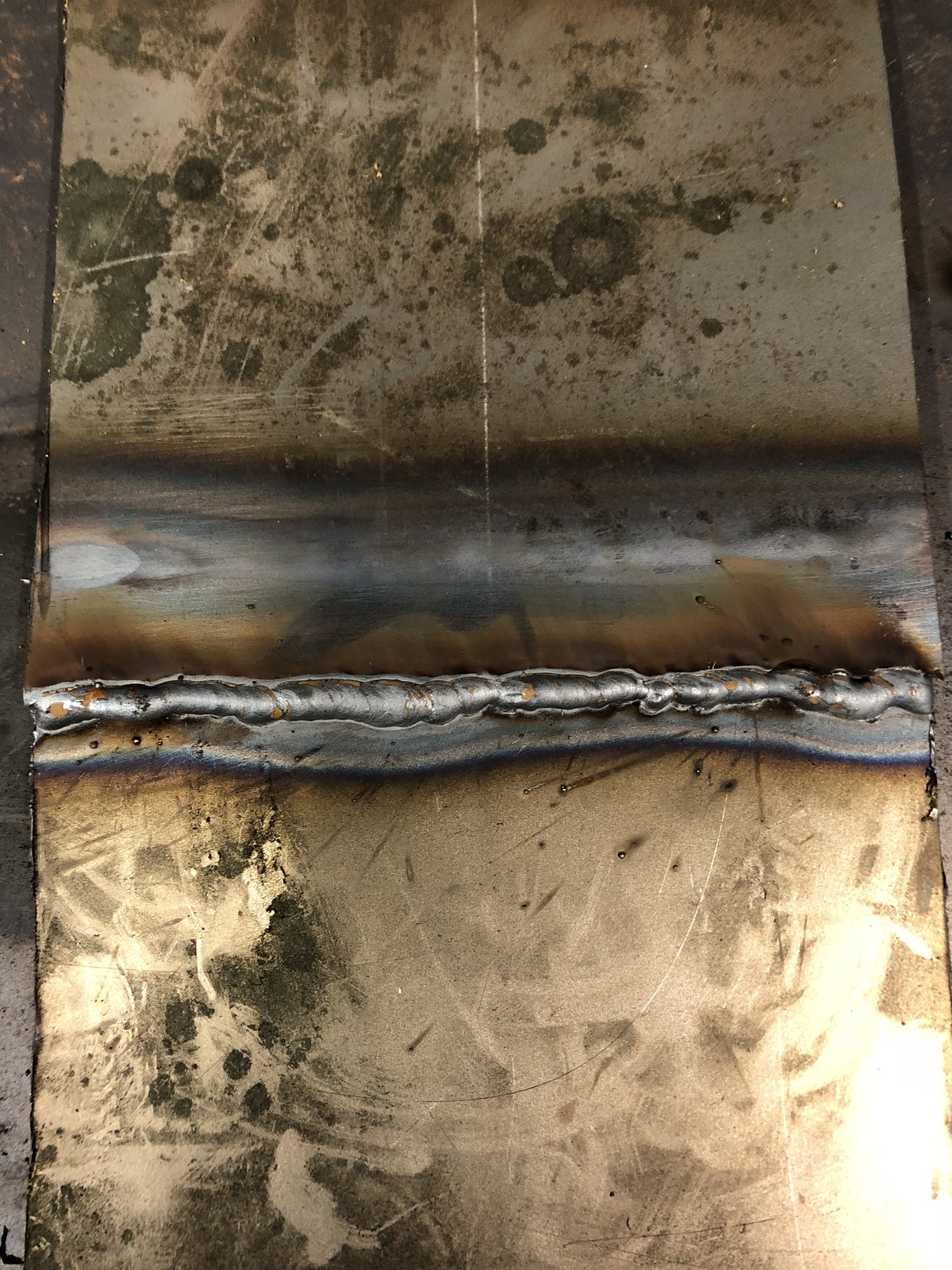

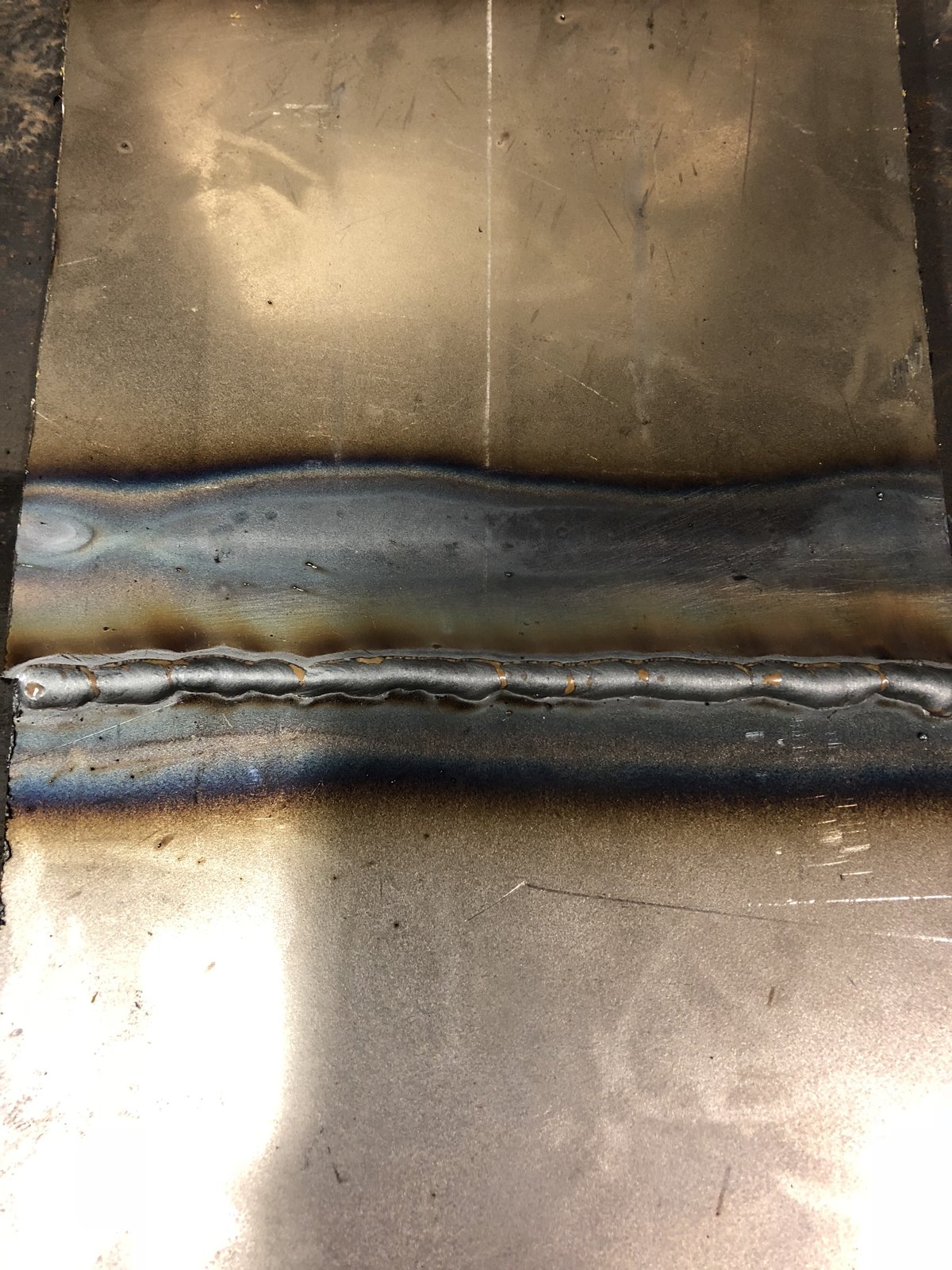

Hello, I’ve never welded in my life and decided to jump in and have a go. These are my first welds just having a play. If I can have your feedback of what’s wrong and right about them and any advise? I think they got better as I went along but might be wrong.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How do these welds look?

- Thread starter TommyGuns

- Start date

Richard.

Member

- Messages

- 18,347

- Location

- Cambridgeshire

As Matt said your travel speed is a little quick but mainly it’s inconsistent.

I’d also suggest knocking the wire speed down a smidge to get the voltage to wet out a bit more.

I wouldn’t worry about penetration too much it’s pretty clear they have bit into the material and you don’t have to come right through the back side for the weld to be sound. What you don’t want is lack of fusion and you are getting this with the inconsistency in the speed. I can see unwelded edges on pics 1 and 4 and cold laps throughout all the joints. This will sort itself out with a constant speed and a little drop in wire speed.

I’d also suggest knocking the wire speed down a smidge to get the voltage to wet out a bit more.

I wouldn’t worry about penetration too much it’s pretty clear they have bit into the material and you don’t have to come right through the back side for the weld to be sound. What you don’t want is lack of fusion and you are getting this with the inconsistency in the speed. I can see unwelded edges on pics 1 and 4 and cold laps throughout all the joints. This will sort itself out with a constant speed and a little drop in wire speed.

Not too good but they got better the more you did, try using your other hand as well to balance the one that holds the torch and let it slide over the work or bench to maintain a consistent arc. The arc will mimic what the torch does so if the torch slows down for a split second it will get wider/taller, if you move the torch tip up a tiny bit, it will also show that in the weld bead, move the torch a smidge faster and the bead will get thinner, so the trick is smooth consistent movements with a constant height and speed. Once you have that down pat then you can look at adjusting voltages/wire speed to get the right type of bead necessary for a good weld.

Shedendman

Member

- Messages

- 5,207

And wear some better footwear you'll be amazed how a tiny bit of spatter burns through,and it blinking hurts

Richard Stowe

Member

- Messages

- 259

- Location

- Potter Heigham

Hi tommyguns

What mig are you using? With what settings?

What mig are you using? With what settings?