Hi guys,

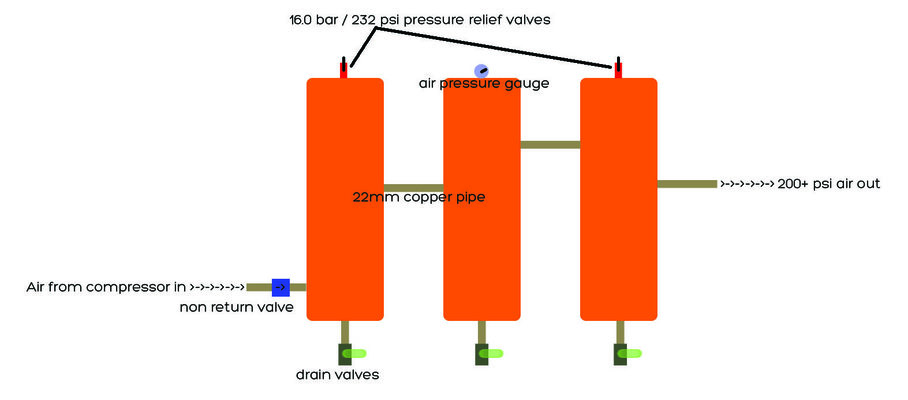

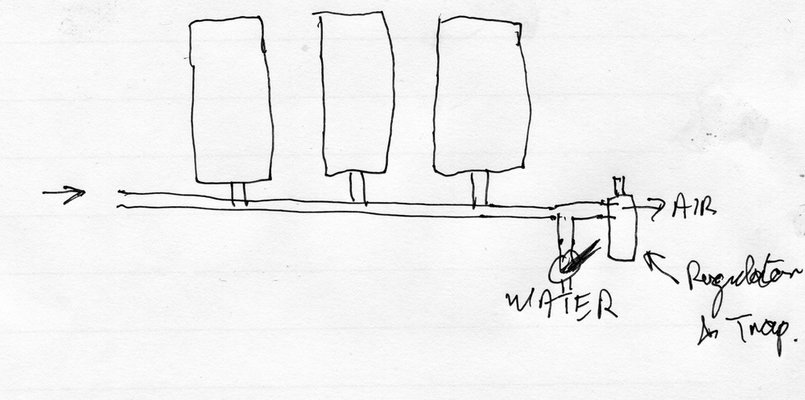

Looking for some advice on building this air receiver tank.

Recently acquired 3 big gas bottles, I want to make an air receiver tank for more air/ higher pressure output.

Currently my 3hp compressor (150 psi) is only giving me about 8-10 secs max power on certain air tools, if this tank(s) give me x3 more time (30 secs) then I would be happy with that, would it give me that?

Cheers for any input

Looking for some advice on building this air receiver tank.

Recently acquired 3 big gas bottles, I want to make an air receiver tank for more air/ higher pressure output.

Currently my 3hp compressor (150 psi) is only giving me about 8-10 secs max power on certain air tools, if this tank(s) give me x3 more time (30 secs) then I would be happy with that, would it give me that?

Cheers for any input