eSCHEn

Bit Wrangler

- Messages

- 6,136

- Location

- SW Scotland

It's a friend's child's birthday coming soon and I'm going to make a swing for him that will live in their garden. It will be a repeat of one I made four years ago that is still standing well. There'll (hopefully) be a few improvements along the way. Rough idea is a metal ridge tube and wooden 'A' frames on each side. The bottom of the frames' legs is braced using another piece of wood. Here's a picture of the previous one I made in all its filthy glory.

The OH wanted to use that weird basket thing and it rotted out last year. I'll need to make something more robust to replace it but that's another swing for another time

First step was to acquire some tube for the ridge. As always, I like to over spec to make up for my engineering shortcomings Shout went out in the wanted section and @slim_boy_fat sorted me with some old scaffolding tube with a nice thick wall

Shout went out in the wanted section and @slim_boy_fat sorted me with some old scaffolding tube with a nice thick wall

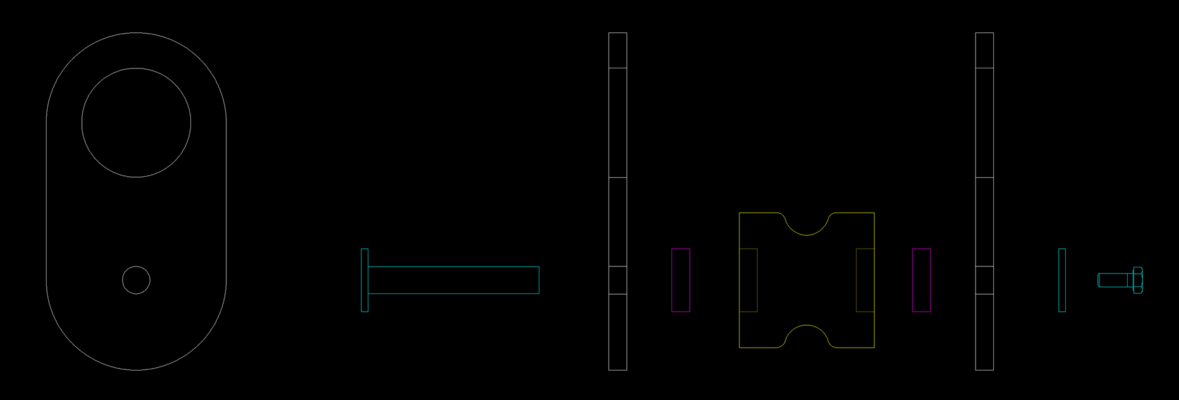

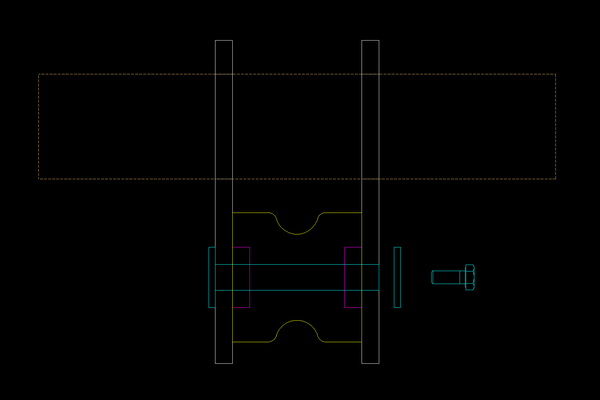

Diameter is 48.5mm with a 3.5mm wall. Raw length is 1335mm.

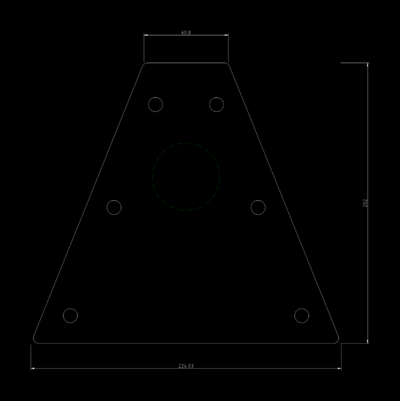

Now in the first model I used what I had – obtainium. I'd recently done a bit of skip rummaging (with permission) and recovered some bits from office furniture which made up a leg of sorts. I welded two of those end-to-end to get the length I wanted and that formed the internal span. I inset the swinging brackets to match the basket width below and provide clearance.

One of the improvements I want to make is form a cover over these exposed end grains. Even though they are still completely sound I would still like this new model to have permanent protection.

This time I'm fresh outta luck and office furniture so I must fabricate (lol at my bodging being called fabricate) from scratch

New post to reset the image limit

The OH wanted to use that weird basket thing and it rotted out last year. I'll need to make something more robust to replace it but that's another swing for another time

First step was to acquire some tube for the ridge. As always, I like to over spec to make up for my engineering shortcomings

Shout went out in the wanted section and @slim_boy_fat sorted me with some old scaffolding tube with a nice thick wall

Shout went out in the wanted section and @slim_boy_fat sorted me with some old scaffolding tube with a nice thick wall

Diameter is 48.5mm with a 3.5mm wall. Raw length is 1335mm.

Now in the first model I used what I had – obtainium. I'd recently done a bit of skip rummaging (with permission) and recovered some bits from office furniture which made up a leg of sorts. I welded two of those end-to-end to get the length I wanted and that formed the internal span. I inset the swinging brackets to match the basket width below and provide clearance.

One of the improvements I want to make is form a cover over these exposed end grains. Even though they are still completely sound I would still like this new model to have permanent protection.

This time I'm fresh outta luck and office furniture so I must fabricate (lol at my bodging being called fabricate) from scratch

New post to reset the image limit

However, the OH was feeling guilty about not contributing to this joint gift that I am making so she volunteered to do it and I am not going to say no

However, the OH was feeling guilty about not contributing to this joint gift that I am making so she volunteered to do it and I am not going to say no

He insisted on a go after dinner as well and wasnae happy going to bed either

He insisted on a go after dinner as well and wasnae happy going to bed either