truckdoctor

Member

- Messages

- 247

I'm not sure if this is the correct section to post, but here goes.

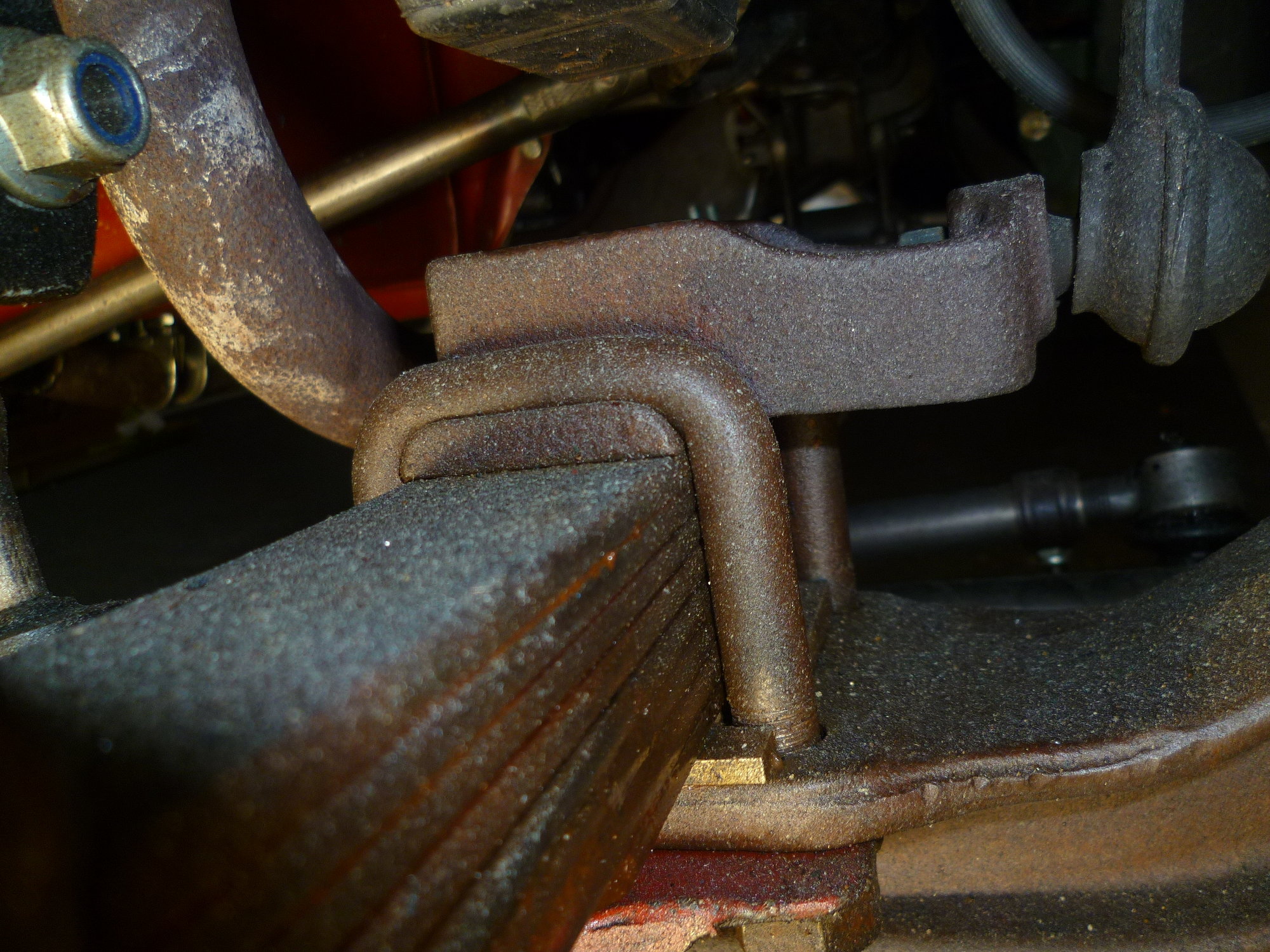

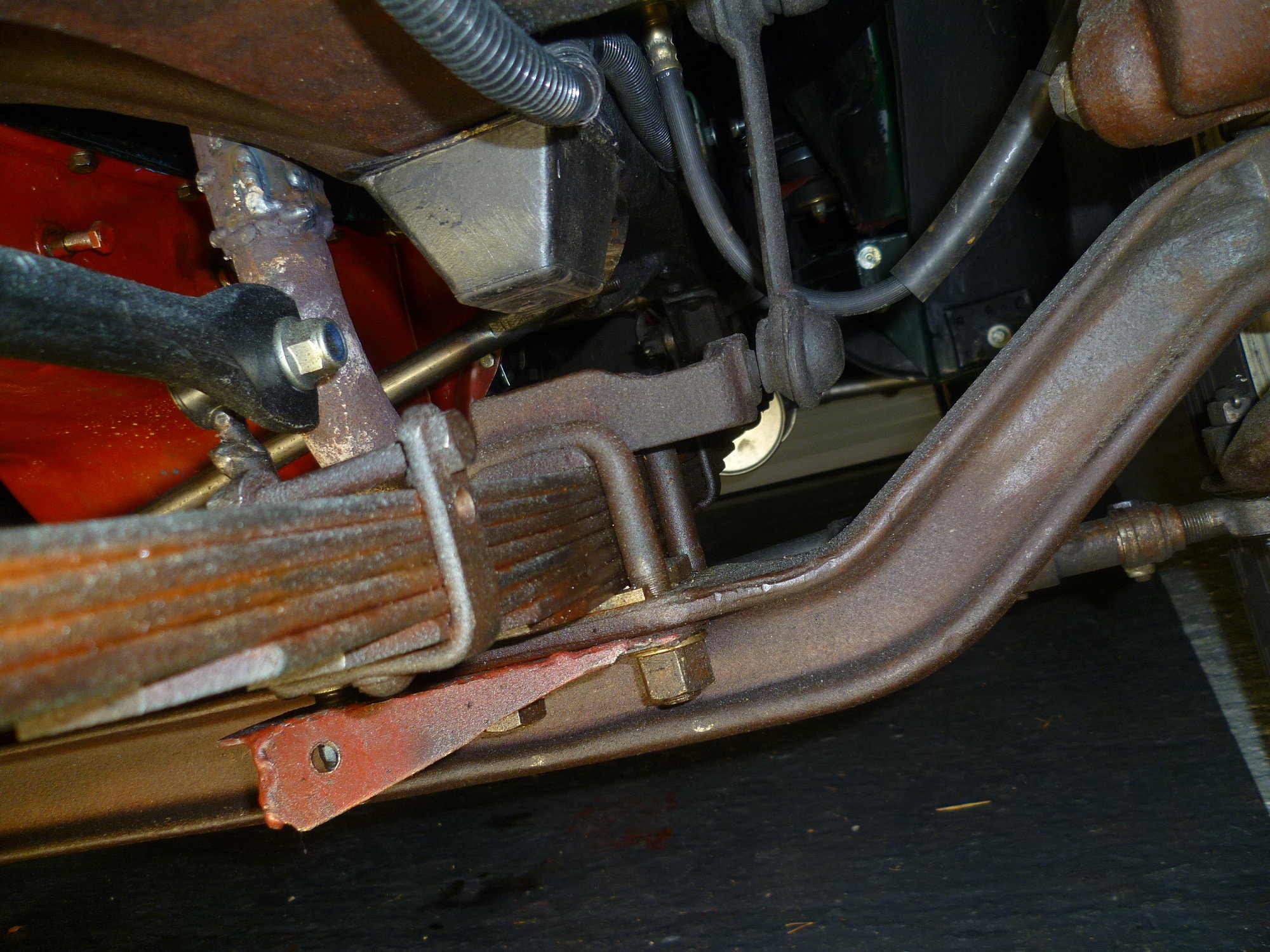

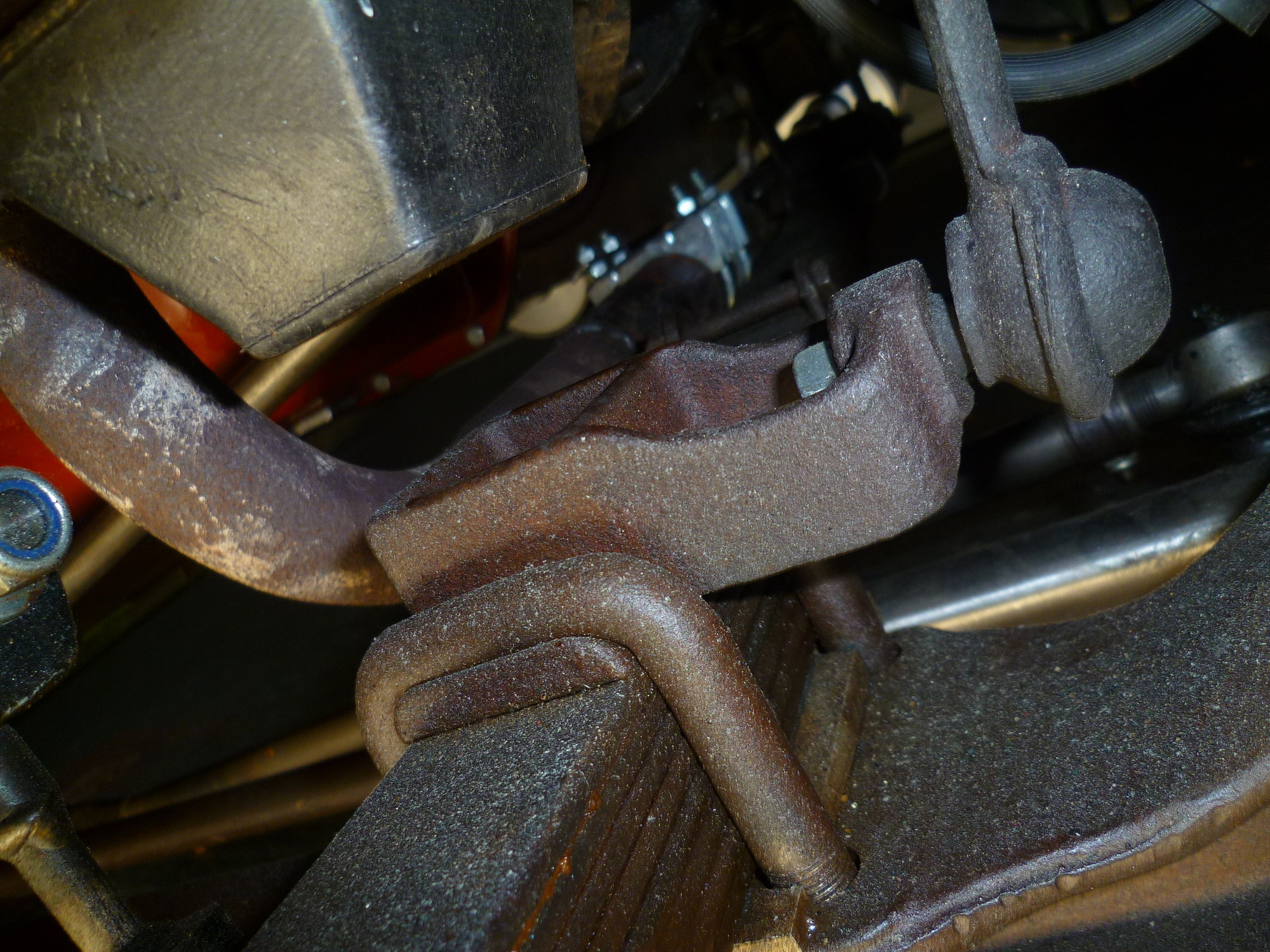

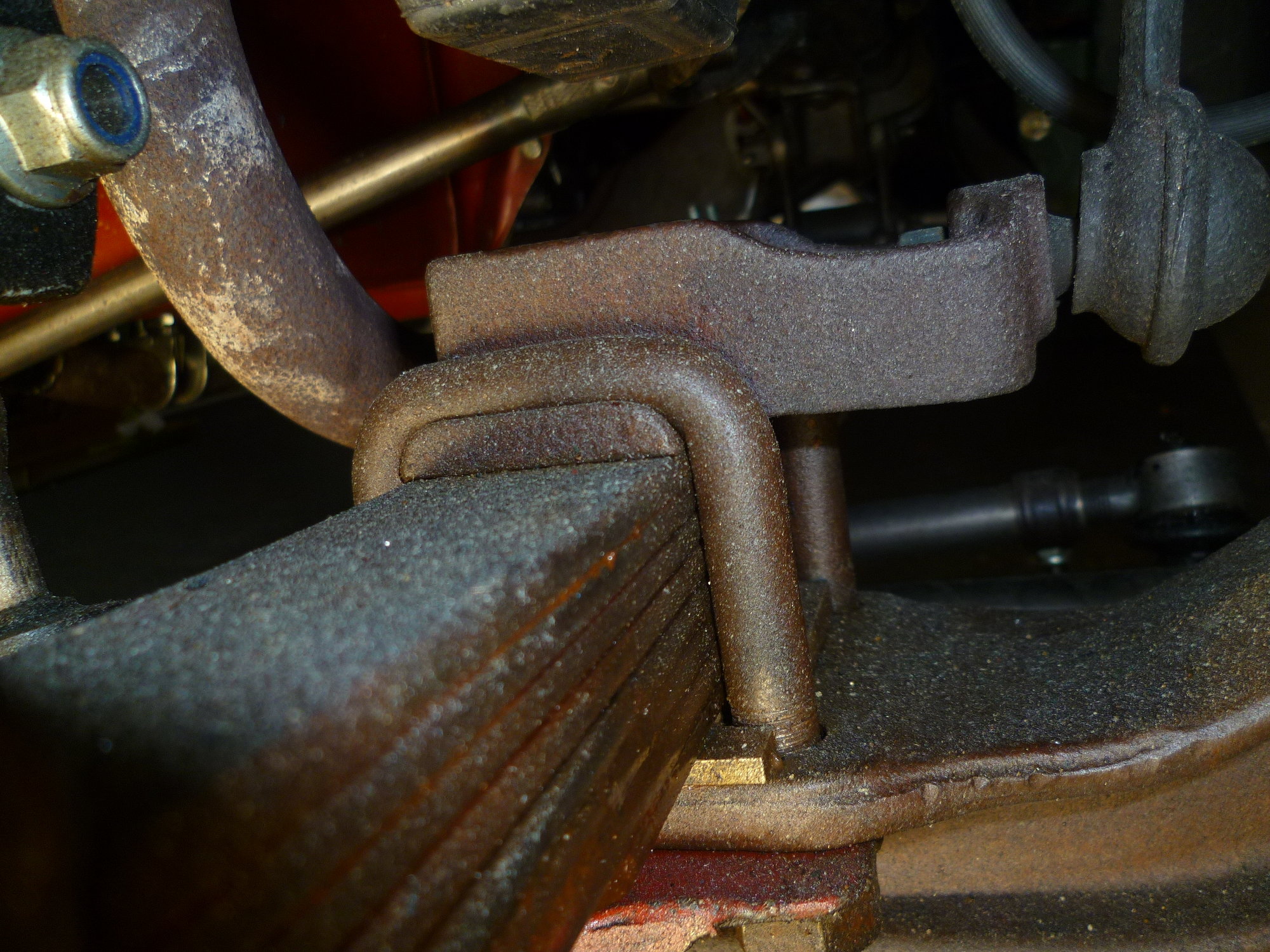

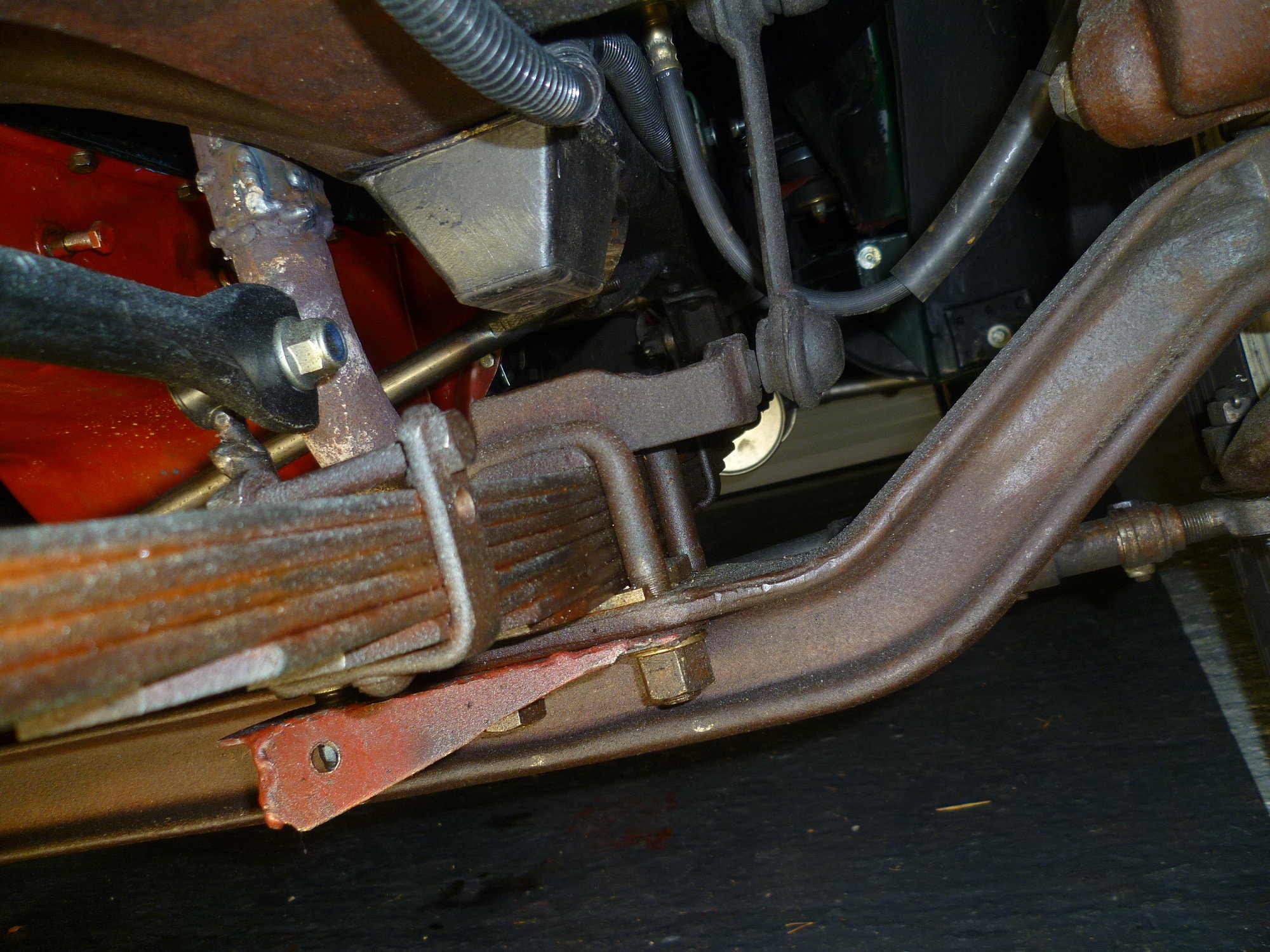

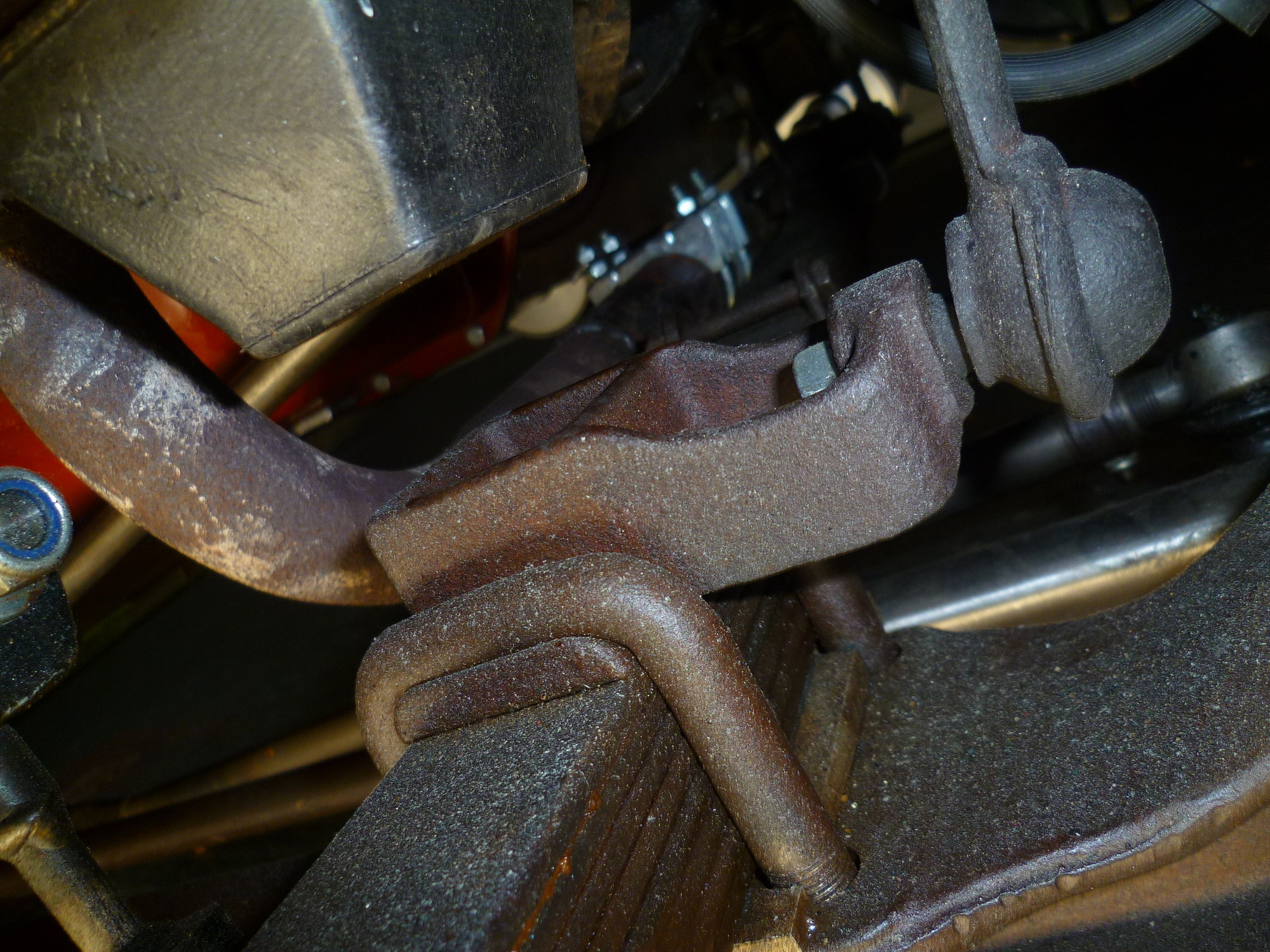

Looking for advice from learned folk hear as to weather these shackles are forged or bent. I need new longer replacement ones and think it would be difficult for me to bend mild steel bar at such a tight 90 degree angle in the shed. I'm thinking maybe replace with bolts instead , what advice do you have please? The width of the leaf spring is 50mm and shackle diameter is 13.3mm

Looking for advice from learned folk hear as to weather these shackles are forged or bent. I need new longer replacement ones and think it would be difficult for me to bend mild steel bar at such a tight 90 degree angle in the shed. I'm thinking maybe replace with bolts instead , what advice do you have please? The width of the leaf spring is 50mm and shackle diameter is 13.3mm