Fintray

Forum Supporter

- Messages

- 832

- Location

- Aberdeenshire (UK)

Some pictures of my gasifying wood burning boiler build (still in progress) that may be of interest.

5mm steel plate for the build

Boiler tube end plates

Faithful Startrite drill and Starrett 73mm holesaw

Schedule XXS 6" to 4" concentric reducer for gasification nozzle

Schedule 40 90 degree long bends

Holes cut in front panel for cleaning and loading doors

Bending steel round nozzle to create air passage for secondary air

Holes drilled in nozzle for secondary air 4 x 10mm

Steel ring welded round nozzle

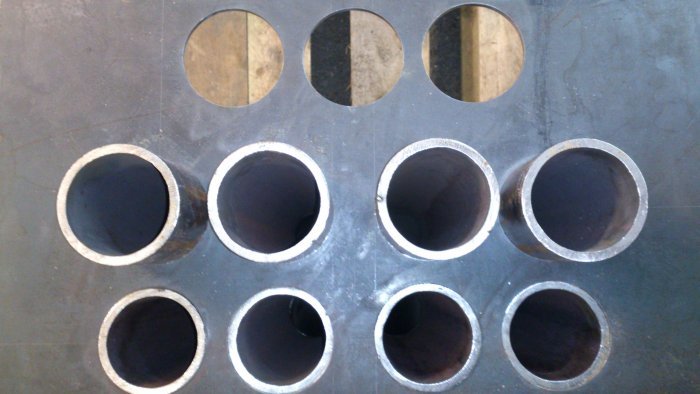

First test fit of boiler tubes to end plates

5mm steel plate for the build

Boiler tube end plates

Faithful Startrite drill and Starrett 73mm holesaw

Schedule XXS 6" to 4" concentric reducer for gasification nozzle

Schedule 40 90 degree long bends

Holes cut in front panel for cleaning and loading doors

Bending steel round nozzle to create air passage for secondary air

Holes drilled in nozzle for secondary air 4 x 10mm

Steel ring welded round nozzle

First test fit of boiler tubes to end plates

-

DSC_0325.jpg44 KB · Views: 3,774

DSC_0325.jpg44 KB · Views: 3,774 -

DSC_0326.jpg49.4 KB · Views: 3,667

DSC_0326.jpg49.4 KB · Views: 3,667 -

DSC_0327.jpg157.8 KB · Views: 3,566

DSC_0327.jpg157.8 KB · Views: 3,566 -

DSC_0335.jpg42.7 KB · Views: 3,554

DSC_0335.jpg42.7 KB · Views: 3,554 -

DSC_0338.jpg58.7 KB · Views: 3,573

DSC_0338.jpg58.7 KB · Views: 3,573 -

DSC_0334.jpg101.9 KB · Views: 3,537

DSC_0334.jpg101.9 KB · Views: 3,537 -

DSC_0333.jpg133.5 KB · Views: 3,552

DSC_0333.jpg133.5 KB · Views: 3,552 -

DSC_0339.jpg57.2 KB · Views: 3,543

DSC_0339.jpg57.2 KB · Views: 3,543 -

DSC_0340.jpg45.3 KB · Views: 3,551

DSC_0340.jpg45.3 KB · Views: 3,551 -

DSC_0350.jpg48.4 KB · Views: 3,618

DSC_0350.jpg48.4 KB · Views: 3,618 -

DSC_0341.jpg53.3 KB · Views: 3,706

DSC_0341.jpg53.3 KB · Views: 3,706 -

DSC_0349.jpg62.8 KB · Views: 3,914

DSC_0349.jpg62.8 KB · Views: 3,914

Last edited: