Milkybars

Member

- Messages

- 1,151

- Location

- Essex

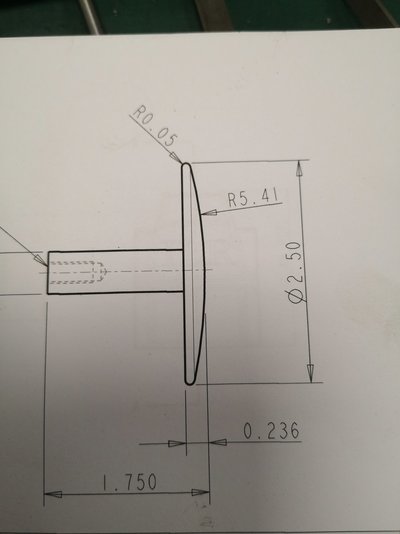

Looking for a bit of assistance, got a few of these to make (out of 304 stainless)

Currently I have enough material for 1, so mondays task will be to source some more.

Anyway, I have never done this before and wondered if someone could assist with guidance on programing the DRO. The little ball turning attachment won't assist me on this occasion

Currently I have enough material for 1, so mondays task will be to source some more.

Anyway, I have never done this before and wondered if someone could assist with guidance on programing the DRO. The little ball turning attachment won't assist me on this occasion