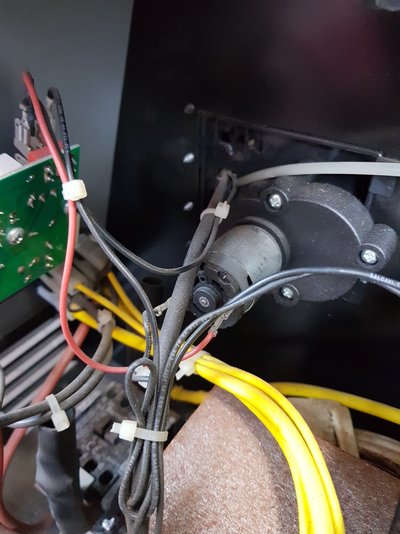

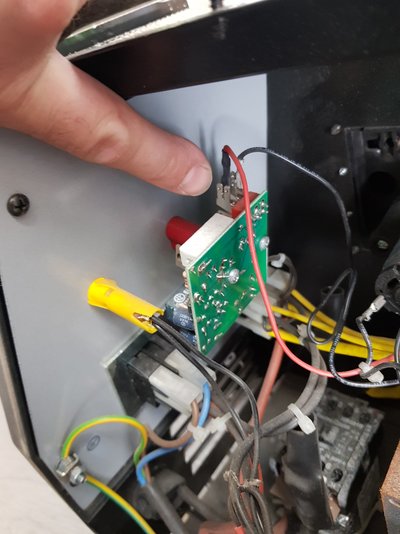

I have a snap on mig 2135. I leant it out and the torch came back broken. A mate suggested i convert it to euro torch so i ordered a kit...... i only had a single feed to the gun? Can anyone advise on whats needed please? The gas hose is now bigger and new torch as 2 wires instead of one?

Regards, paul

Regards, paul