- Messages

- 2,886

- Location

- Never Never Land

I thought I’d make another post so I can document my progress.

Today I spent about £40 on 6m of copper and a load of little connections to make it work

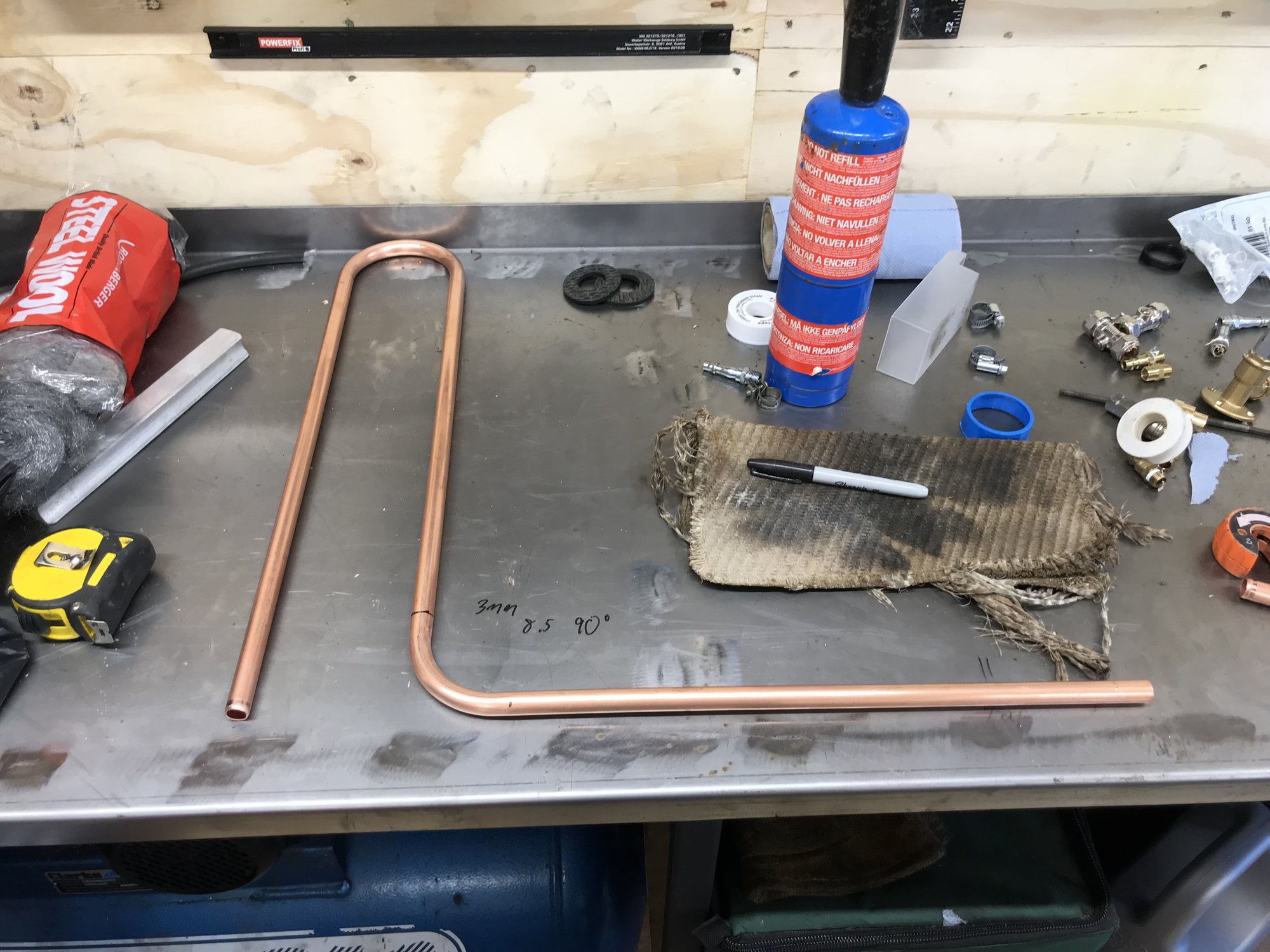

I started by doing this. It was in a difficult place so I made that first, I put a drain on the bottom.looking at this I think I’m going to twist the 90 bend round the the right a bit. Because I’m making it so the compressor and table can be easily moved I have the copper here, on the other end of the full bore tap is a pipe connector barb thing. That will connect to the bottom of the air cooler.

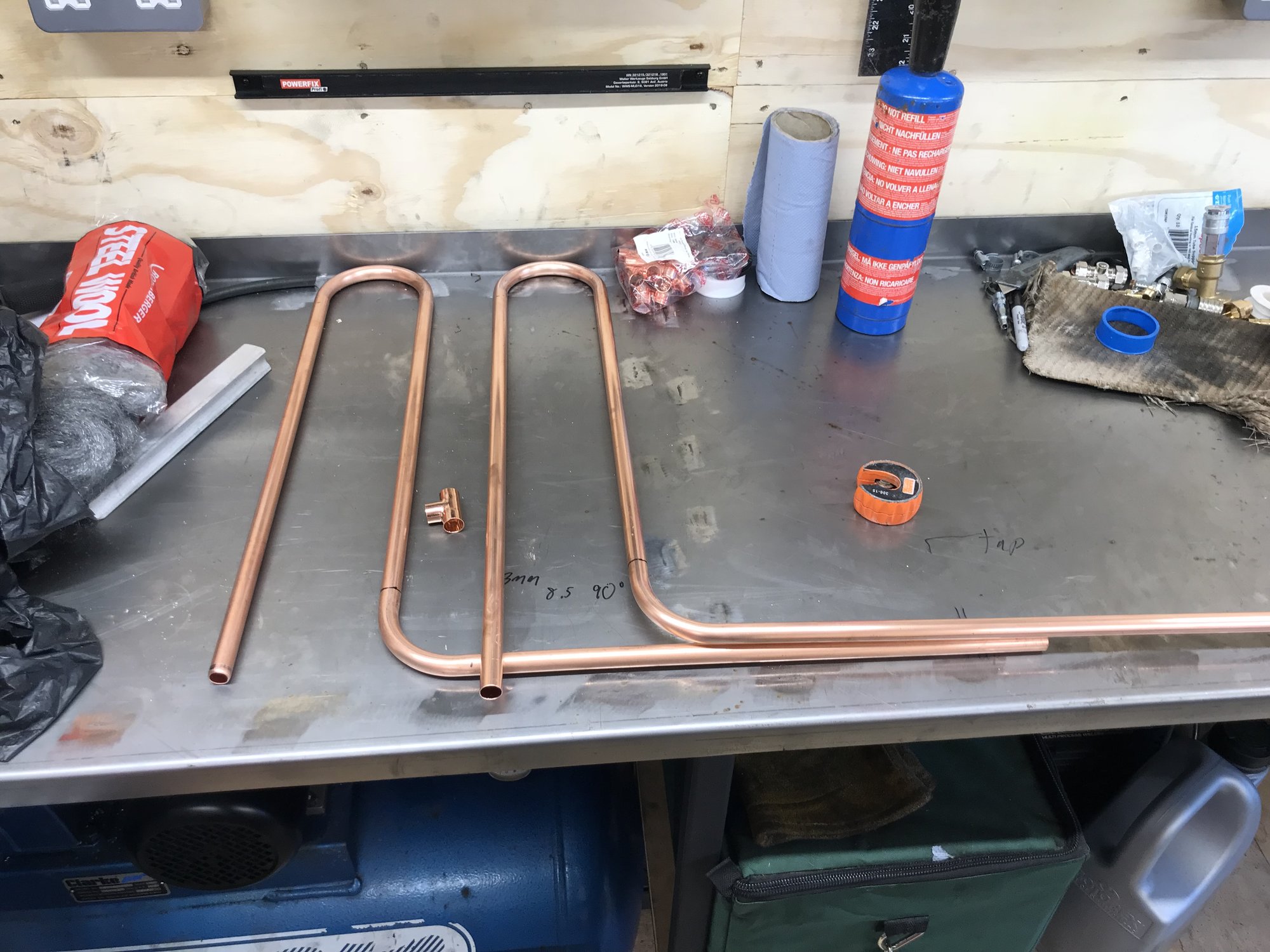

First loop of the air cooler. I decided to bend as much as I could, looks nicer and is more practical with air flow

Duplicated

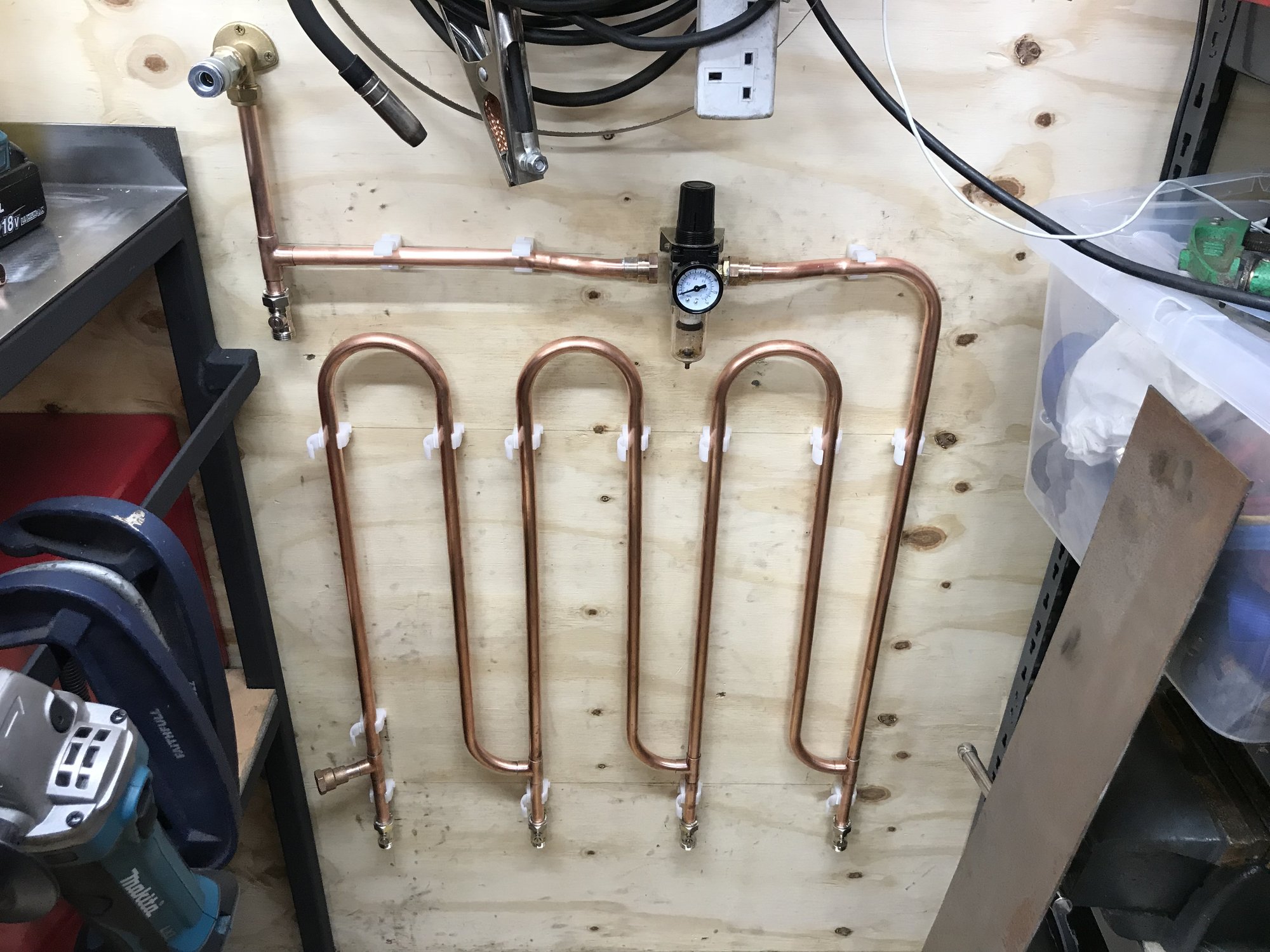

Trebled

Put the connection for the regulator on top

And at the bottom left you can see the connection for the compressor in I have high flow quick connector to go on there so I can move the bench quickly and easily.

Just finally, regulator on I am missing two brass reducers on the Reg and one on the inlet feed. I’ll pick that up next week and finish this up. It’s come out well I think.

Today I spent about £40 on 6m of copper and a load of little connections to make it work

I started by doing this. It was in a difficult place so I made that first, I put a drain on the bottom.looking at this I think I’m going to twist the 90 bend round the the right a bit. Because I’m making it so the compressor and table can be easily moved I have the copper here, on the other end of the full bore tap is a pipe connector barb thing. That will connect to the bottom of the air cooler.

First loop of the air cooler. I decided to bend as much as I could, looks nicer and is more practical with air flow

Duplicated

Trebled

Put the connection for the regulator on top

And at the bottom left you can see the connection for the compressor in I have high flow quick connector to go on there so I can move the bench quickly and easily.

Just finally, regulator on I am missing two brass reducers on the Reg and one on the inlet feed. I’ll pick that up next week and finish this up. It’s come out well I think.

If the tank every rots through I’ll just buy a matching new one so everything can be switched about

If the tank every rots through I’ll just buy a matching new one so everything can be switched about