citizen kane

Member

- Messages

- 245

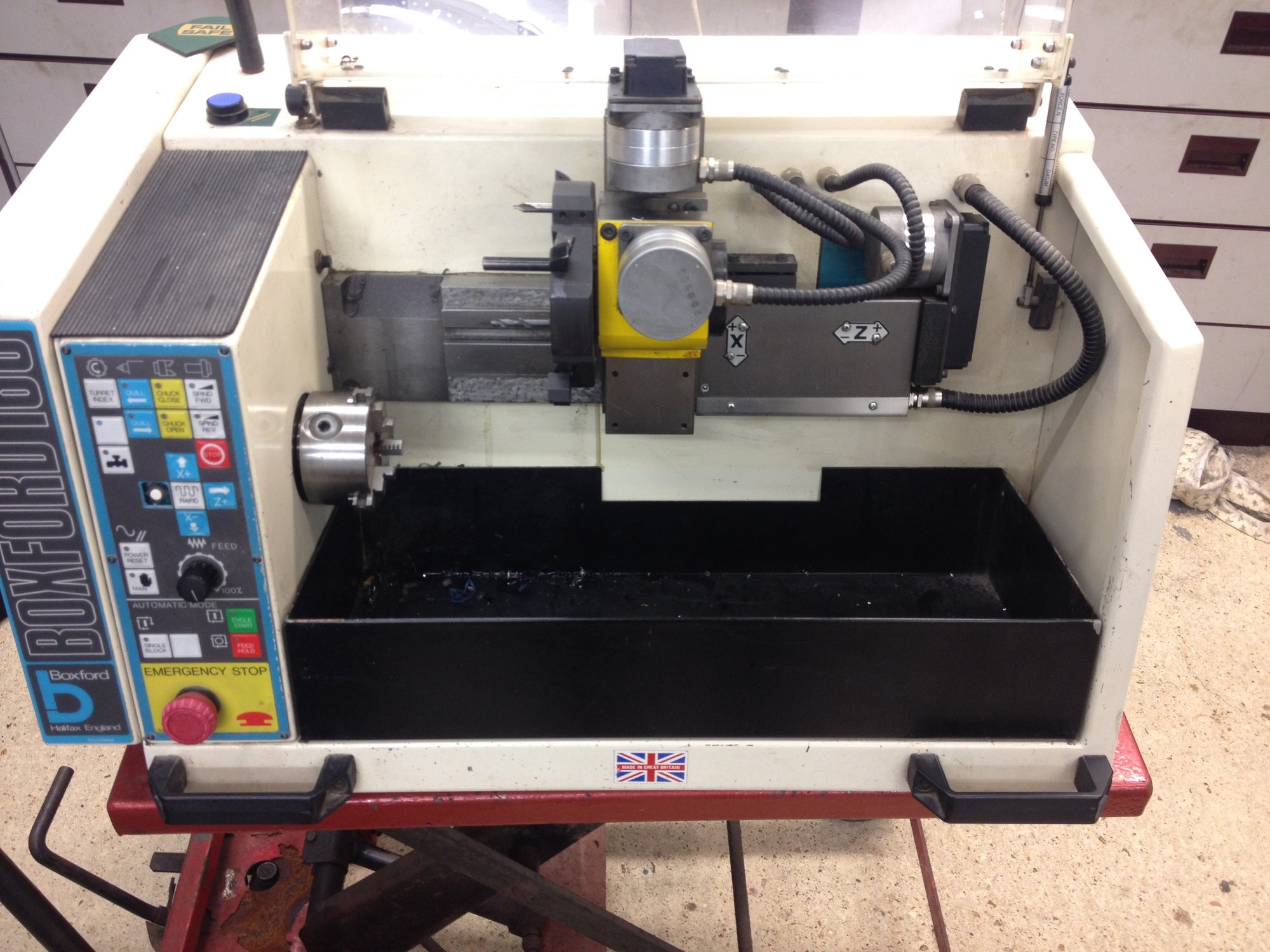

I wasn't looking for one, it kind of found me and now I don't know what to do.

After a couple of hours fiddling it came to life and amazingly it all seems to work. Using the buttons on the front I can control all the axis and spindle. Unfortunately the lathe came with no computer to control it so what do I do now.

Does anyone have any experience with these things, can I just buy some software and plug in a computer or is it infernally complicated to get these things working. Very much out of my depth but willing to learn.

After a couple of hours fiddling it came to life and amazingly it all seems to work. Using the buttons on the front I can control all the axis and spindle. Unfortunately the lathe came with no computer to control it so what do I do now.

Does anyone have any experience with these things, can I just buy some software and plug in a computer or is it infernally complicated to get these things working. Very much out of my depth but willing to learn.