Gareth0123

You'll need 16 pigs to do the job in one sitting!

- Messages

- 1,559

- Location

- Norwich, Norfolk, UK

(very) Occasionally I will do a little MMA welding on a job that comes in. Often these jobs are too big for me to get through the workshop doors or it is easier to just not unload them from the trailer they were delivered on, etc.

For the past four years I have used my dual voltage 110/240 volt X 200amp dc Tig machine, plugging the torch and return into the available dinse sockets on the machine's front panel. Normally my TIG lives on a shelf and is attached to a cylinder of Argon and I have to disconnected it from the cylinder to do a 5 minute MMA job, so for two years I considered purchasing a dedicated single phase MMA inverter welder for these small jobs.... maybe only a maximum of two or three hours of work per year.

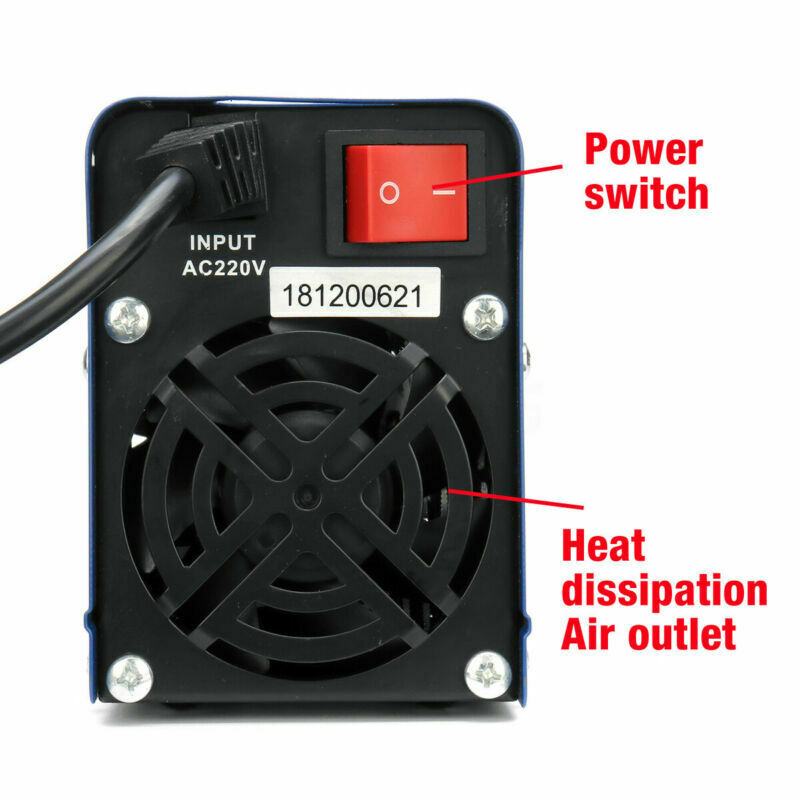

So I shopped around with cheapness rather than brand loyalty being my priority in this particular instance. This is what I found on ebay for £34.99 so I thought "Well, it's a Blue one, I'll give it a punt" ..... it has since risen in price twice from the date of my original purchase.

So I bought it on Monday 12th of August and it arrived directly from China on Saturday 24th of August. It was delivered by Royal Mail, although the box it came in was just and I mean just a little too large to post through our standard letter box.

Just to make it absolutely clear, I deliberately purchased this welder as a bare unit without a mains plug, without leads, without a return clamp or electrode holder, and without any other accessories such as chipping hammer, cheapo-dodgy mask, etc.

You can buy more expensive versions of this welder with these items and accessories including a plastic storage case if you want to, but basically I did not want any more low quality leads or cheap welding accessories cluttering up my workshop...………… I have several reasonable quality spare sets of MMA leads and torches, etc that were supplied with both my Mig & Tig plants when they were new.

For the past four years I have used my dual voltage 110/240 volt X 200amp dc Tig machine, plugging the torch and return into the available dinse sockets on the machine's front panel. Normally my TIG lives on a shelf and is attached to a cylinder of Argon and I have to disconnected it from the cylinder to do a 5 minute MMA job, so for two years I considered purchasing a dedicated single phase MMA inverter welder for these small jobs.... maybe only a maximum of two or three hours of work per year.

So I shopped around with cheapness rather than brand loyalty being my priority in this particular instance. This is what I found on ebay for £34.99 so I thought "Well, it's a Blue one, I'll give it a punt" ..... it has since risen in price twice from the date of my original purchase.

So I bought it on Monday 12th of August and it arrived directly from China on Saturday 24th of August. It was delivered by Royal Mail, although the box it came in was just and I mean just a little too large to post through our standard letter box.

Just to make it absolutely clear, I deliberately purchased this welder as a bare unit without a mains plug, without leads, without a return clamp or electrode holder, and without any other accessories such as chipping hammer, cheapo-dodgy mask, etc.

You can buy more expensive versions of this welder with these items and accessories including a plastic storage case if you want to, but basically I did not want any more low quality leads or cheap welding accessories cluttering up my workshop...………… I have several reasonable quality spare sets of MMA leads and torches, etc that were supplied with both my Mig & Tig plants when they were new.

Last edited: