KETTENKRAD

New Member

- Messages

- 4

- Location

- UK. Essex

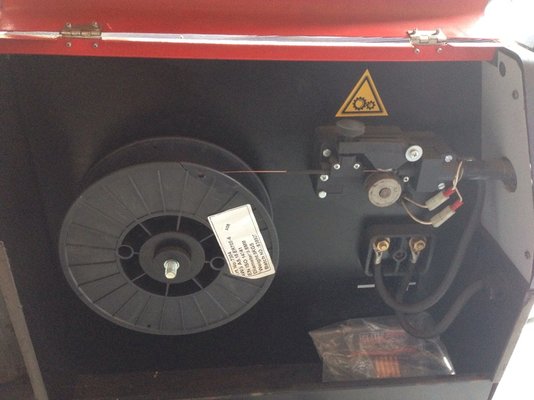

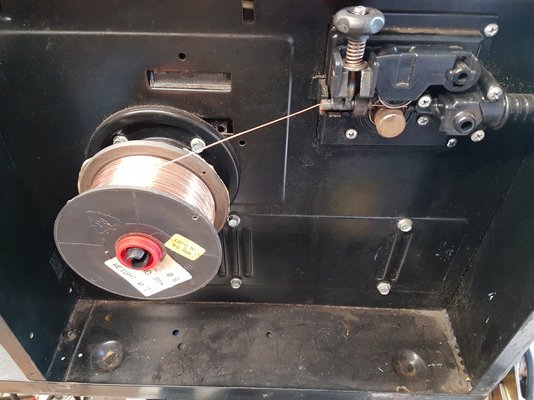

Hi, Anyone have images of what the spool and wire feed should look like please ?

The second hand 130 unit I just purchased looks very awkward, pulling the wire from the spool at an angle. Also can I fit a 5kg spool to this machine ?

Thanks.

The second hand 130 unit I just purchased looks very awkward, pulling the wire from the spool at an angle. Also can I fit a 5kg spool to this machine ?

Thanks.