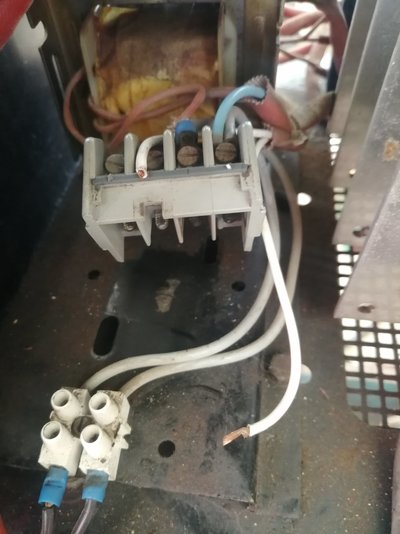

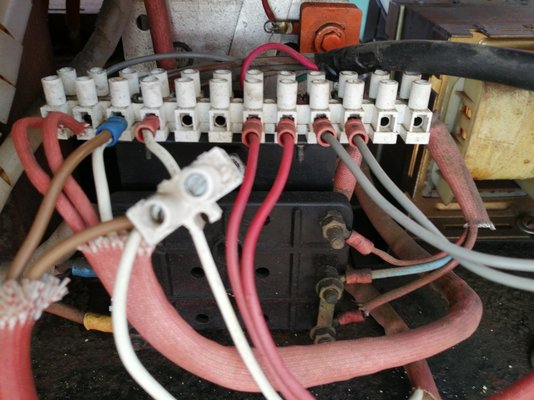

Hello guys, first time in the forum, i have a cebora magna 150 special car matricula 2766, my problem is then the electrovalve its always electrised, i changed the contactor and check the electrovalve,they look fine to me, weeks before, a friend replace the switched potentiometer, i think i could move some cables , if someone have similar machine and could send a photo of the pcb and connections, i always be thankfull.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cebora Magna 150 Special Car

- Thread starter cid

- Start date

"Special Car" - that is a new brand name to me. Turns out it became Cebora:

"The CEBORA brand quickly became a reference name in the welding field, both in the domestic market and in several foreign markets (particularly Europe and South America) and, already in the ‘60s and ‘70s; export is an important share of the company turnover.

Early ‘80s, CEBORA takes over the company Special Car, manufacturer of MIG welding machines of (for those years) advanced technology.

It is the start of a new period of growth and of research of new products, all destined to be a remarkable international success. In 1984, the CEBORA Technical Department, with its strong team of skilled and motivated technicians, invents the first portable MIG/MAG welding machine (Pocket MIG), which is an immediate and extraordinary sales success, both in Europe and in the USA."

Was the welding power range switch replaced? There do seem to be some random loose wires, not easy to fix without a schematic or another machine to compare.

To start, what are the operating coil voltages on the gas valve and the contactor? Could be 12v, 24v, AC or DC, or 220v AC. That may help to decide what component is responsible for controlling the gas valve, such as a relay or a Triac.

"The CEBORA brand quickly became a reference name in the welding field, both in the domestic market and in several foreign markets (particularly Europe and South America) and, already in the ‘60s and ‘70s; export is an important share of the company turnover.

Early ‘80s, CEBORA takes over the company Special Car, manufacturer of MIG welding machines of (for those years) advanced technology.

It is the start of a new period of growth and of research of new products, all destined to be a remarkable international success. In 1984, the CEBORA Technical Department, with its strong team of skilled and motivated technicians, invents the first portable MIG/MAG welding machine (Pocket MIG), which is an immediate and extraordinary sales success, both in Europe and in the USA."

Was the welding power range switch replaced? There do seem to be some random loose wires, not easy to fix without a schematic or another machine to compare.

To start, what are the operating coil voltages on the gas valve and the contactor? Could be 12v, 24v, AC or DC, or 220v AC. That may help to decide what component is responsible for controlling the gas valve, such as a relay or a Triac.

Yes, I see it now ! If this component is faulty ( i.e. short-circuit ) , or the logic circuit which triggers it is permanently high, that would explain the gas valve fault. However, we need to confirm that this is a Triac, and that it does feed the gas valve..... only !

With the Contactor operating coil also being 24v AC, does this Triac feed both ? If so, the Contactor would also always be on, and I think it is not on. Maybe there are two Triacs ?

Anyway, I would suggest unsoldering the Triac that you have found, and checking if the gas valve is no longer always energised.

With the Contactor operating coil also being 24v AC, does this Triac feed both ? If so, the Contactor would also always be on, and I think it is not on. Maybe there are two Triacs ?

Anyway, I would suggest unsoldering the Triac that you have found, and checking if the gas valve is no longer always energised.

Hello Eddie good day from Mexico and an apology for not responding before I was out of town for work,

I have replaced the triac and reconnected the original contactor the problem continues, and the contactor its always on,

What happens if I turn off the power of the solenoid valve and connect it to the switch of the mig gun?

I have replaced the triac and reconnected the original contactor the problem continues, and the contactor its always on,

What happens if I turn off the power of the solenoid valve and connect it to the switch of the mig gun?

Buenas tardes ! As I understand it, you have found that the main Contactor is driven by the same Triac as the solenoid valve, and both of them are always on?

This implies that the rest of the logic on the PCB is telling the Triac to switch on - by raising the trigger signal to the Triac gate. You could confirm this by identifying which pin is the gate, and temporarily disconnecting it. With that condition, the Triac should not be on, and the Contactor and solenoid valve should open ( i.e. relax ). The gate voltage is typically about 5 volts.

The MIG torch switch will connect to the PCB logic, and is supposed to activate three circuits - the Contactor, the gas solenoid, and the wirefeed. Are you sure that the torch switch is not short-circuit?

This implies that the rest of the logic on the PCB is telling the Triac to switch on - by raising the trigger signal to the Triac gate. You could confirm this by identifying which pin is the gate, and temporarily disconnecting it. With that condition, the Triac should not be on, and the Contactor and solenoid valve should open ( i.e. relax ). The gate voltage is typically about 5 volts.

The MIG torch switch will connect to the PCB logic, and is supposed to activate three circuits - the Contactor, the gas solenoid, and the wirefeed. Are you sure that the torch switch is not short-circuit?