abdel hakam E. Soliman

New Member

- Messages

- 3

- Location

- Egypt

Hello professionals

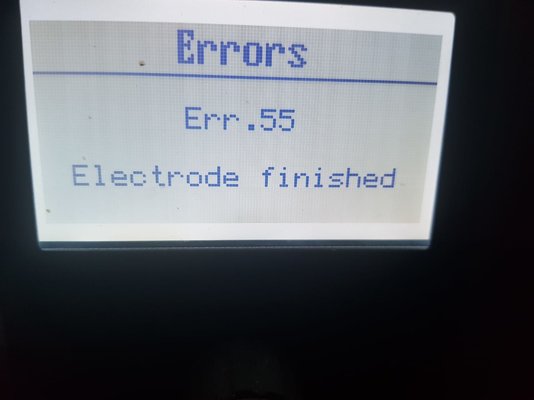

I have a new Cebora plasma cutter which called Plasma Sound PC 110/T

When I installed it on my CNC tables and began working

A message appears on its screen stated: "Electrode finished"

Note:

This message appears randomly now and in all cases it occurs, consumables are new"electrode and nozzle'

The air pressure is little more than 5.5 bars and we have 2 air filters and dryer (all are new)

The compressor is restarts at 7 bars pressure

I have a new Cebora plasma cutter which called Plasma Sound PC 110/T

When I installed it on my CNC tables and began working

A message appears on its screen stated: "Electrode finished"

Note:

This message appears randomly now and in all cases it occurs, consumables are new"electrode and nozzle'

The air pressure is little more than 5.5 bars and we have 2 air filters and dryer (all are new)

The compressor is restarts at 7 bars pressure