Richard.

Member

- Messages

- 18,347

- Location

- Cambridgeshire

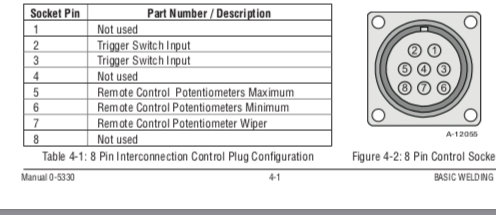

Does your machine have a thermal arc 8pin socket?

Mine does and it’s been long over due to sort out the torch/pedal swapping about.

So I built a remote. Conventional switch to turn the pedal on/off and a socket in the front to connect up the torch. Problem is machine has a glitch where it goes into remote without the remote on. Service engineer said to me it requires a short across pot minimum and wiper in torch mode. And that’s as far as I got on my own.

A member on here @pdg I’ve been in contact with over last few days has taken my remote to a whole new level and I’d like to share the info with other TA and tweco owners. All the wiring and design is from Pdg and his patience has managed to get me to understand it and wire it to work.

I can turn the pedal on and off. I can do this now without the fault due to the short been in place in the off position.

I can plug my torch in and my pedal in at the same time.

The clever bit is I can now pre set a pedal start current which is something I couldn’t do before. Now I can throw up all the drawings on here for people to copy but I’m gonna leave that with Pdg as it’s his drawing and he made it work.

All I did was fabricate the remote and slap it together

I can’t thank Pdg enough and I hope this info gets others in a similar position cos it’s a major upgrade to that thermal arc interface.

Mine does and it’s been long over due to sort out the torch/pedal swapping about.

So I built a remote. Conventional switch to turn the pedal on/off and a socket in the front to connect up the torch. Problem is machine has a glitch where it goes into remote without the remote on. Service engineer said to me it requires a short across pot minimum and wiper in torch mode. And that’s as far as I got on my own.

A member on here @pdg I’ve been in contact with over last few days has taken my remote to a whole new level and I’d like to share the info with other TA and tweco owners. All the wiring and design is from Pdg and his patience has managed to get me to understand it and wire it to work.

I can turn the pedal on and off. I can do this now without the fault due to the short been in place in the off position.

I can plug my torch in and my pedal in at the same time.

The clever bit is I can now pre set a pedal start current which is something I couldn’t do before. Now I can throw up all the drawings on here for people to copy but I’m gonna leave that with Pdg as it’s his drawing and he made it work.

All I did was fabricate the remote and slap it together

I can’t thank Pdg enough and I hope this info gets others in a similar position cos it’s a major upgrade to that thermal arc interface.