Tim Humphries

New Member

- Messages

- 7

- Location

- Gloucestershire

I'm no welder, but there seems to be a few Boxford users on here who can maybe help? Had my AUD 5" a while but haven't used it for the last couple of years (long story).

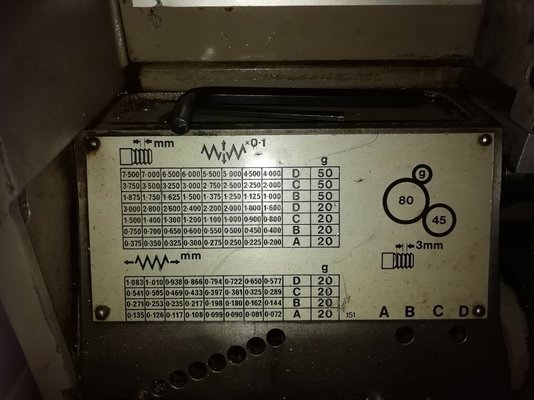

Last time I used it was for a bit of thread cutting so the headstock gears were positioned accordingly. Trouble is, I didn't note the original setup. I cannot now remember the headstock gear set-up for ordinary surfacing work, nor can I find it described anywhere.

I feel a bit of a plonker to have to ask, but I wonder if someone would be kind enough to post a pic of their setup or maybe an online reference please?

Last time I used it was for a bit of thread cutting so the headstock gears were positioned accordingly. Trouble is, I didn't note the original setup. I cannot now remember the headstock gear set-up for ordinary surfacing work, nor can I find it described anywhere.

I feel a bit of a plonker to have to ask, but I wonder if someone would be kind enough to post a pic of their setup or maybe an online reference please?