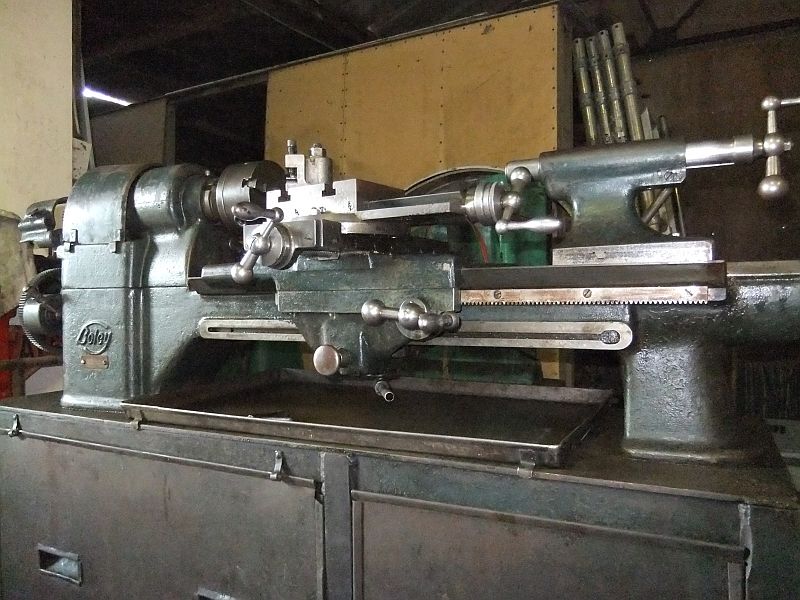

Today i picked up a Boley 4LE lathe, a scrappy mate acquired it a couple of years ago & its been sitting around since then. Last week he said, "Its been hanging around too long i might as well weigh it in".

It is such a finely made thing i couldnt see it scrapped so bought it on the spot.

Got it home this morning. Its 2" longer than a Myford super 7 but considerably heavier. Box of bits with it, collet chuck with 30 Hardinge collets, fixed & travelling steadies & a full set of changewheels including the 127 tooth one for metric or imp conversion.

I have seen a lot of machines but the build quality of this is simply superb. Think i shall be doing a proper nice job of this one. Interestingly it has a little copper plate just below the name that says SR 1954 presumably its first owner.

It is such a finely made thing i couldnt see it scrapped so bought it on the spot.

Got it home this morning. Its 2" longer than a Myford super 7 but considerably heavier. Box of bits with it, collet chuck with 30 Hardinge collets, fixed & travelling steadies & a full set of changewheels including the 127 tooth one for metric or imp conversion.

I have seen a lot of machines but the build quality of this is simply superb. Think i shall be doing a proper nice job of this one. Interestingly it has a little copper plate just below the name that says SR 1954 presumably its first owner.