brockenhammer

Member

- Messages

- 272

- Location

- Freiburg, Germany

Hi,

I just made a series of pictures from a typical job I do recently.

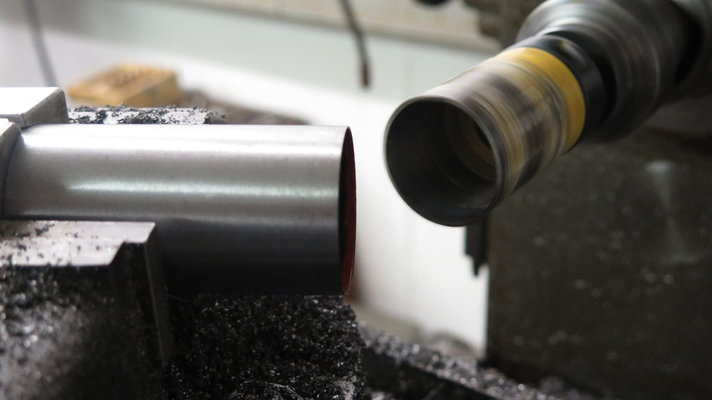

The steel touring frame had a bad dent in the downtube and filling that with silversolder (Thats what I do when it´s not as bad) wouldn´t work.

So I had to replace the tube......

I just made a series of pictures from a typical job I do recently.

The steel touring frame had a bad dent in the downtube and filling that with silversolder (Thats what I do when it´s not as bad) wouldn´t work.

So I had to replace the tube......

![IMG_4064[1].JPG](/forum/data/attachments/196/196278-755beb2a48d0c29ecbbd6fec17e1eeef.jpg)