Brad93

Member

- Messages

- 17,570

- Location

- Essex, United Kingdom

I’m starting a new contract next week that involves quite a bit of welding of 5/6mm sheet.

All MIG onsite (indoors).

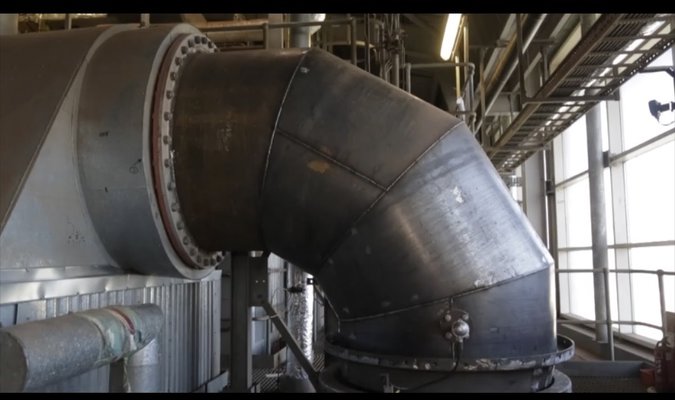

It’s a load of sheet metal ductwork so cutting out damage, plating repairs, making new lobster backs up to about 72”.

Now I’m okay a Mig but it’s been years since I’ve done such thin stuff that’s not box section etc. Just having a play on 4mm in the workshop and I’ve got the butt welds dialed in on a 2G using about 2.5mm gap but really struggling with doing a 3G.

I’ve tried various gaps but it’s just coming out really poor.

Any tips?

All MIG onsite (indoors).

It’s a load of sheet metal ductwork so cutting out damage, plating repairs, making new lobster backs up to about 72”.

Now I’m okay a Mig but it’s been years since I’ve done such thin stuff that’s not box section etc. Just having a play on 4mm in the workshop and I’ve got the butt welds dialed in on a 2G using about 2.5mm gap but really struggling with doing a 3G.

I’ve tried various gaps but it’s just coming out really poor.

Any tips?