You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone have a Migatronic Pi 200

- Thread starter DrNik

- Start date

wheresmejumper

Banned

- Messages

- 2,626

brokenbiker

Member

- Messages

- 10,437

- Location

- Llanbobyll, south wales

that looks more complicated than my meganes wiring loom lol

DrNik

Heath Robinsons long lost son

- Messages

- 1,455

On the flat, got some 1,2,3,4,5,6mm Ali and I'd just love to lay down some acceptable beads really, seems like whatever I do it looks like never looks a glossy clean bead, always black bits, pops fart, and i can break the welds with little effort, looks like it needs more cleaning action, but its at 80% and as Scotty said " If I give her anymore captain I think she is going to blow"

brokenbiker

Member

- Messages

- 10,437

- Location

- Llanbobyll, south wales

just my 2p worth but what happens when you turn the balance right down? some machines work opposite to others?

obviously if you are adjusting it according to the manual then im out of ideas as I don't know a lot about ac balance really, just something I can remember reading

obviously if you are adjusting it according to the manual then im out of ideas as I don't know a lot about ac balance really, just something I can remember reading

DrNik

Heath Robinsons long lost son

- Messages

- 1,455

That's it, think I need that Data bloke

Tigman

Forum Supporter

- Messages

- 3,736

- Location

- Watford UK

aluminium clean ? what tungsten you using ? are you using upslope and down slope ? dont worry about pulse till you can run a short bead on flat , no butts til you can run a bead , my machine is way over my head too but I just keep playing with the settings till it comes right !

If you haven't got the manual then it's available here... http://www.migatronic.com/product finder/machines/industry/automation/pi

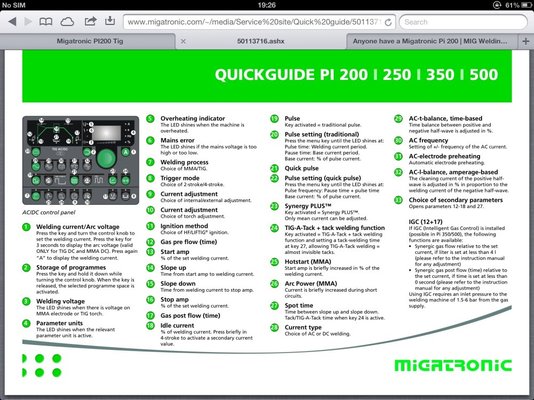

Not trying to be a smartarse but it's all pretty standard TIG stuff with the exception of being able to alter AC balance in two ways... the tradtional one (% EN) and amperage i.e. the amperage during the EP (cleaning) phase can be altered between 30 and 170% of the welding current.

Most of the bells and whistles can be ignored or set once and forgotten about. Especially if using a footpedal. The manual gives the default settings as

which with the exception of 0secs preflow (and some slope time if using the torch button, say 0.5 secs slope up and 1 - 3 secs slope down depending on material and amperage) are in the ball park i.e. usable on most stuff if not ideal. Set the pre flow to 0.5sec and then forget about it. The settings i've reduced the font size are all to do with pulse and so can be completely ignored unless using pulse

Start, stop amperages are set as % so will pretty much take care of themselves as you vary the main amperage. Start amperage % can be used to provide a hot start which is useful for ally i.e. set it to over 100% and the arc will start hotter and come down to welding amperage according to the slope time in secs

Electrode preheating is a gizmo that alters the amount of EP used when striking an arc with AC. Turning it up will melt the tip of the tungsten more. Can be pretty much ignored if you want, before it existed this was done manually by striking up on a piece of scrap or just left to happen while welding

The default AC (time) balance is 65% EN. Turning it UP reduces the amount of 'cleaning' according to the manual

The default AC (amperage) balance is 100% which is traditional i.e. same amperage for EN and EP

The default AC frequency is 50% which is what a traditional transformer machine is stuck at. Higher AC frequencies constrict the arc and so are useful for fillets, especially on thin ally. Several threads with more indepth explanations in the tig forum for example... http://www.mig-welding.co.uk/forum/threads/waveshapes.37420/#post-412262

ETA mislabelled the 'second current level' setting. The manual explains it, only active when in 4T, basically torch button can be used in a 'posh way' as well as just on/off

Not trying to be a smartarse but it's all pretty standard TIG stuff with the exception of being able to alter AC balance in two ways... the tradtional one (% EN) and amperage i.e. the amperage during the EP (cleaning) phase can be altered between 30 and 170% of the welding current.

Most of the bells and whistles can be ignored or set once and forgotten about. Especially if using a footpedal. The manual gives the default settings as

It is possible to recall all factory standard parameters.

In this case all programs in the machine will be reset

to the following value:

MMA current 80A

TIG Current 80A

TIG Spot Current 80A

Pre-flow 0.0 sec

Post-flow 6.0 sec

No slope-up/slope-down

Start amp 40%

Stop amp 20%

Second Current level 50%

Base amp 40%

Fast pulse frequency 49Hz

Pause time = Pulse time = 0.1 sec

AC-T-Balance (AC) 65%

Electrode Pre-heating (AC) 5

Frequency (AC) 50%

AC-I-Balance (AC) 100%

which with the exception of 0secs preflow (and some slope time if using the torch button, say 0.5 secs slope up and 1 - 3 secs slope down depending on material and amperage) are in the ball park i.e. usable on most stuff if not ideal. Set the pre flow to 0.5sec and then forget about it. The settings i've reduced the font size are all to do with pulse and so can be completely ignored unless using pulse

Start, stop amperages are set as % so will pretty much take care of themselves as you vary the main amperage. Start amperage % can be used to provide a hot start which is useful for ally i.e. set it to over 100% and the arc will start hotter and come down to welding amperage according to the slope time in secs

Electrode preheating is a gizmo that alters the amount of EP used when striking an arc with AC. Turning it up will melt the tip of the tungsten more. Can be pretty much ignored if you want, before it existed this was done manually by striking up on a piece of scrap or just left to happen while welding

The default AC (time) balance is 65% EN. Turning it UP reduces the amount of 'cleaning' according to the manual

The default AC (amperage) balance is 100% which is traditional i.e. same amperage for EN and EP

The default AC frequency is 50% which is what a traditional transformer machine is stuck at. Higher AC frequencies constrict the arc and so are useful for fillets, especially on thin ally. Several threads with more indepth explanations in the tig forum for example... http://www.mig-welding.co.uk/forum/threads/waveshapes.37420/#post-412262

ETA mislabelled the 'second current level' setting. The manual explains it, only active when in 4T, basically torch button can be used in a 'posh way' as well as just on/off

- Messages

- 21,571

- Location

- Birmingham

Thank you, thank you, the mystical Pandora's box of magic maybe fathomed out, I'll let you know how I get on.....

Or it will be in the "for sale" section next week?

DrNik

Heath Robinsons long lost son

- Messages

- 1,455

Well I've been playing today on a box for he back of my argo, it's about 3mm Ali and it was all going do well, the after fiddling with the miga-chronic all I does is burn back the tungsten and welds it to the cup..... I want some serious tig lessons

If you're properly melting the tungsten then it's either gonna be something like the torch polarity is wrong (always negative unless there's a specific socket labelled TIG torch) and/or balance settings... obviously in AC if the torch polarity is wrong the balance adjustments will be backwards

DrNik

Heath Robinsons long lost son

- Messages

- 1,455

Right has a great day, did lots of welding, looks like I had the cleaning action far to low, causing the tungsten to melt out, so it's not the balance settings round the wrong, so took some general settings off youtube and was very happy with the results, the Ali is all secondhand sheet and isn't very clean, tried to brush it some and grind it clean but looks like the dirt penetrates the surface, but all in all it works actually ok for a doorstop.

DrNik

Heath Robinsons long lost son

- Messages

- 1,455

The important bit is that you got is sorted but FWIW it's too much cleaning (electrode positive) that melts the tungsten

That's what I found out once I'd come in and given up for the night, the ceramic shroud was melting, went through a few of them before I gave up