zeppelin builder

Member

- Messages

- 2,154

- Location

- peoples republic of scotland

Got the clutch

unstuck and gave it a good run up the stubble field like a big organic wire brush

unstuck and gave it a good run up the stubble field like a big organic wire brush

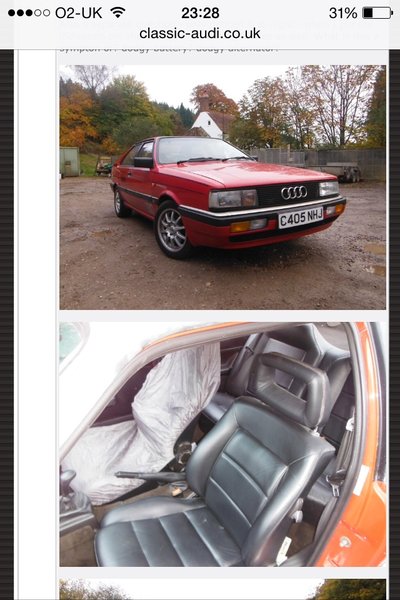

Its still in good nick

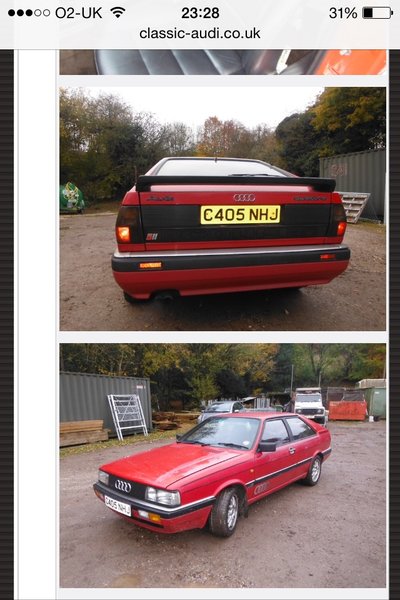

Next I'm do away with the sunroof and start working on it proper

Volvo t5 power soon

Its still in good nick

Next I'm do away with the sunroof and start working on it proper

Volvo t5 power soon