mattbearman

New Member

- Messages

- 18

- Location

- Devon, England

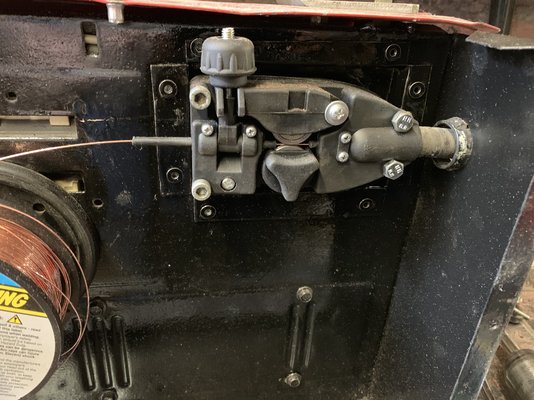

As seems to be pretty common with these welders, the wire feed tensioner on my Snap On MIG 130 has broken, meaning it can't keep tension on the drive wheel and the wire keeps slipping.

Does anyone have a spare or know where I can get one? It seems neither WECS or Weldequip have them in stock. I've just been on the phone to my local BOC shop, and he checked the stock of all BOC shops in the country to no avail.

I'm also sure I saw something about someone successfully fitting a wire feed assembly from a Clarke welder, but I can't find it now.

Cheers,

Matt

Does anyone have a spare or know where I can get one? It seems neither WECS or Weldequip have them in stock. I've just been on the phone to my local BOC shop, and he checked the stock of all BOC shops in the country to no avail.

I'm also sure I saw something about someone successfully fitting a wire feed assembly from a Clarke welder, but I can't find it now.

Cheers,

Matt