Crouchy121

New Member

- Messages

- 12

- Location

- England Worthing

Well this is a sign of things to come. What are you thoughts? I saw something like this a couple of years ago but it was print welding some weird object.

I observed for the first time a 3D printer in action the other day.

It was just one of the cheaper type using plastic filament. As I watched it, the thought came to me how like mig welding the filament coming out was & wondered if you could link a mig welder to a 3D printing rig. Your video shows that its perfectly feasible.

RonA

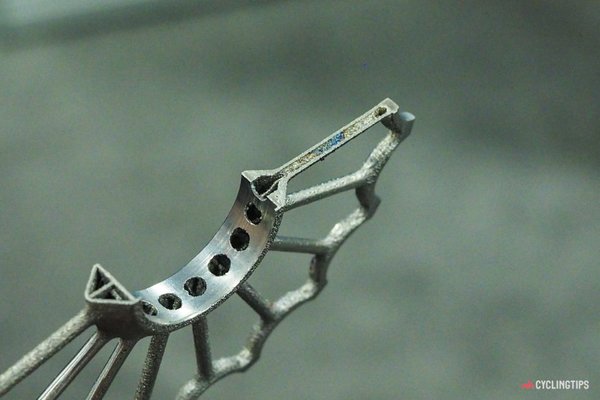

That's Wire + Arc Additive Manufacturing, the walls are typically much smoother in the laser applications but they do have their draw backs too such as strength and time to produce. The parts are typically machined after deposition with WAAM, not so much with laser powder bed

Quality not great.

Most of the new systems use sintered metal - a powder melted by a laser.

Autodesk also did this one, believe it was for a tugWatched a video on damen tugs “printing” a tug prop , that was hellishly impressive

If the inert gas in mig welding is to keep out oxygen, would have thought a vacuum would be great to weld in, no shielding gas req'd.Can you weld in a very cold partial vacuum is the question I suppose ought to be asked first?

I was chatting with a BAE guy at Fairford air show a couple of years back they were talking about printing titanium even then. They could print enclosed parts that would not be possible in normal manufacturing.

This makes for interesting reading.When you (arc) weld in at atmosphere, the gas (Inert or not) is ionised and becomes conductive. As the pressure is reduced, approaching a perfect vacuum, the breakdown voltage increases so it's harder to ionise and form an arc, I don't think you'd get arc welding to work in space.

The limiting factor with getting things into space is the weight anyway, a bigger rocket can be built to carry a bigger (Greater volume) satellite without a huge penalty but a heavier satellite needs a rocket with bigger engines, carrying much more fuel (And the increased weight of the fuel requires even more fuel to carry it, that's why most rockets are multistage and drop their heavy fuel tanks when they empty). The equipment and materials to manufacture a space craft would be an awful lot heavier than a space craft already manufactured on earth.