I thought it was finally time to start a proper build thread for my E30. It’s a rusty 316i that I was building it into a M50 turbo weapon, but I had Gunni at GSTuning build me a manifold for the car, which turned into an absolute disaster. After a year of legal paperwork I took Gunni to small claims court where I won and have a county court judgment order against him.

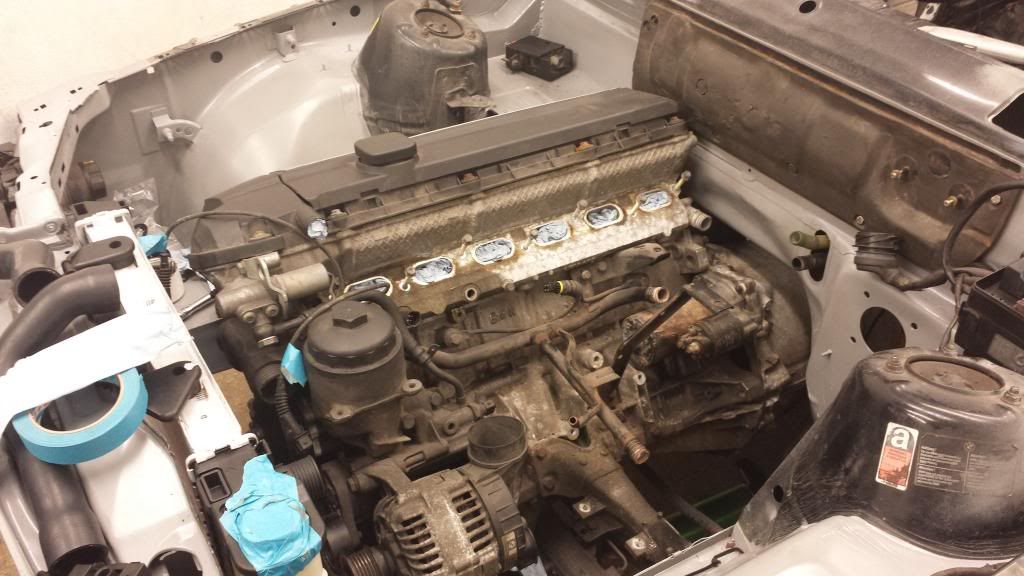

So after a lot of time and my money wasted I decided to just M52 the car and later on decide if I want more power.

Onto the car! It’s a bog standard 1989 E30 316i in Schwarz. I bought it and didn’t realise that there was a lot of hidden rust. So rather than this being a simple engine swap, its turned into a bit of a restoration.

The turd:

It had all the usual rust that an E30 always has, but this E30 had really been neglected and the rust had spread.

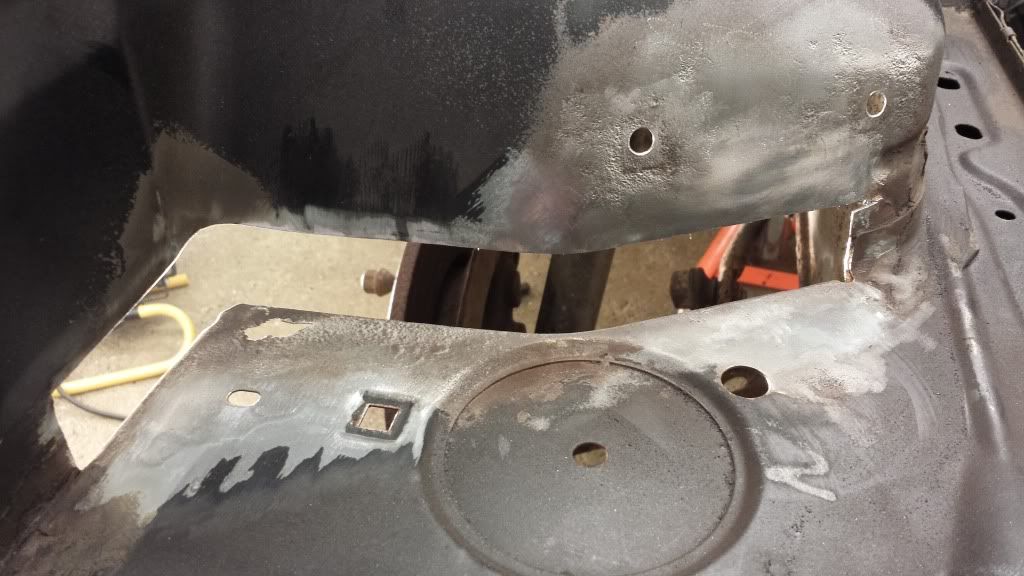

Bung had fallen out at some point:

Cut out and welded:

Primed and seam sealed:

Jacking point rust:

Cut out:

Welded and primed:

Firewall rust:

New sheet metal positioned:

Rear:

Tacked in:

Fully welded and welds smoothed:

Other end:

Welded:

Panel spot welded back in:

So after a lot of time and my money wasted I decided to just M52 the car and later on decide if I want more power.

Onto the car! It’s a bog standard 1989 E30 316i in Schwarz. I bought it and didn’t realise that there was a lot of hidden rust. So rather than this being a simple engine swap, its turned into a bit of a restoration.

The turd:

It had all the usual rust that an E30 always has, but this E30 had really been neglected and the rust had spread.

Bung had fallen out at some point:

Cut out and welded:

Primed and seam sealed:

Jacking point rust:

Cut out:

Welded and primed:

Firewall rust:

New sheet metal positioned:

Rear:

Tacked in:

Fully welded and welds smoothed:

Other end:

Welded:

Panel spot welded back in:

is the rest of the car as bad?

is the rest of the car as bad?