Dye Penetrant

Visible dye penetrant is a NDT (Non Destructive Testing) method. It is a simple test to perform, and a good way to test welds before carrying out more expensive techniques like x-ray testing.

It will show up bad cold lap, cracks, holes... basically any defects where a very fine dye can penetrate, hence the name. It can be used for various things, not just weld testing. Testing for a crack in a cylinder head for example.

The simple kits come in 3 parts, usually in aerosol cans. A cleaner, a penetrant, and a developer. There are four types of dye penetrant system:

- Water washable - the dyes wash away with water.

- Lipophilic - the dye dissolves in oil for removal.

- Hydrophilic - the dye washes away with a water rinse, but detergents are necessary.

- Solvent removable - the dye is removed with a cleaning solvent.

There are five levels of testing, from Level ½ (Lowest sensitivity) to Level 4 (Highest Sensitivity)

Operatives carrying out this testing should be qualified to do so, and reports, sometimes with photographic evidence, might be requested.

|

Step 1 - Pre cleaning First any loose material needs to be removed, together with any silica on top of the weld. It is important to remove the silica, or you can get false results. A good scrape and wire brush sorts this out in most cases. Then apply some of the cleaner to remove any oil etc. Wait for the cleaner to dry completely before applying penetrant. |

|

|

Step 2 - Penetrant Once cleaned, apply the penetrant (a bright red liquid dye). Spray plenty on the welds. Leave the dye to penetrate, normally for about 20 minutes. The time scale is usually printed on the can or on the product data sheet. The photographs show a solvent removable system. |

|

|

Step 3 - Post cleaning Cleaning again. You need to remove excess dye from the area, which is easier said than done. It is important not to spray the cleaner on the area directly, or you risk washing the dye from the flaw. Use a dry tissue to remove excess dye, then spray cleaner onto a clean cloth for final cleaning. |

|

|

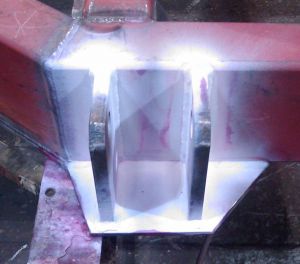

Step 4 - The results Once it's all clean again, you need to spray on the developer, a white substance that dries slightly powdery after a few minutes. The developer draws the remaining dye from any flaws, showing them as very red marks in the brilliant white developer. This particular test had no issues to resolve. You can see the edges of the cleaned area showing a slight redness. If there had been a hole in the weld it would have shown up very clearly as a pink-red spot. |