Brad93

Member

- Messages

- 17,544

- Location

- Essex, United Kingdom

Hi all.

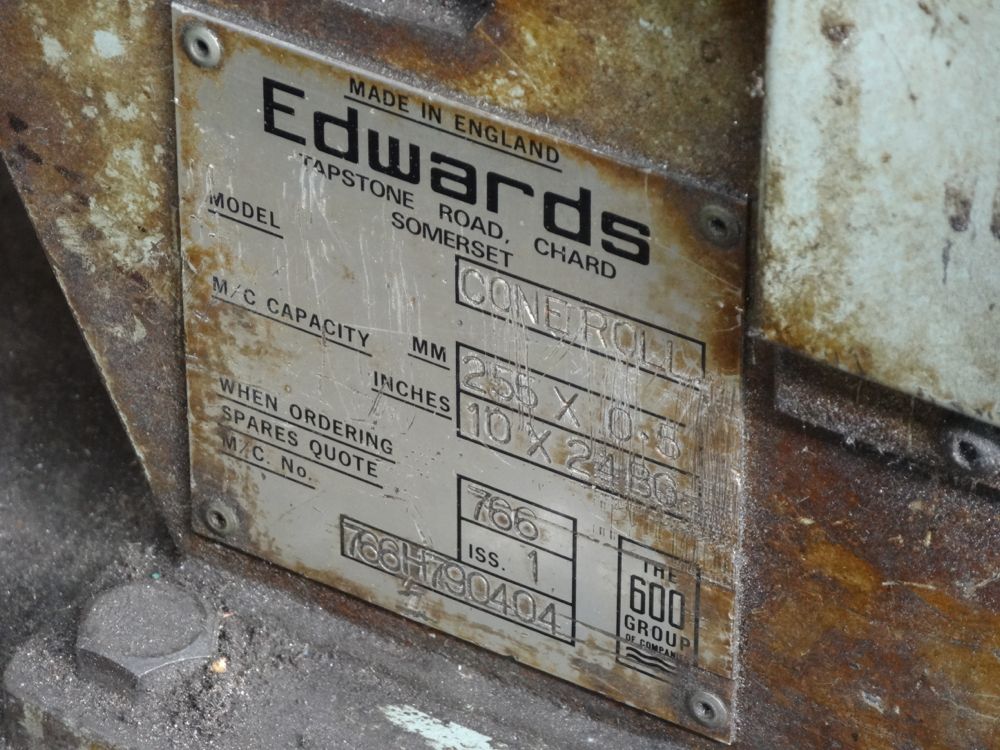

A customer of mine has had these F J Edwards cone rollers for a number of years, but between us we cannot figure out how to roll a cone nicely? There is only a patent number and a serial number on our ones. On a set ive found via google it gives some more specs.

Does anyone know how to set them up?

The first two pictures are our set.

Other pictures are ones from the internet.

A customer of mine has had these F J Edwards cone rollers for a number of years, but between us we cannot figure out how to roll a cone nicely? There is only a patent number and a serial number on our ones. On a set ive found via google it gives some more specs.

Does anyone know how to set them up?

The first two pictures are our set.

Other pictures are ones from the internet.

remember it was thin 20swg or less the boss was forming.

remember it was thin 20swg or less the boss was forming.