Farmerpalmer

New Member

- Messages

- 27

- Location

- Essex/Suffolk border

Hi, I wonder if I could pick your collective brains again?

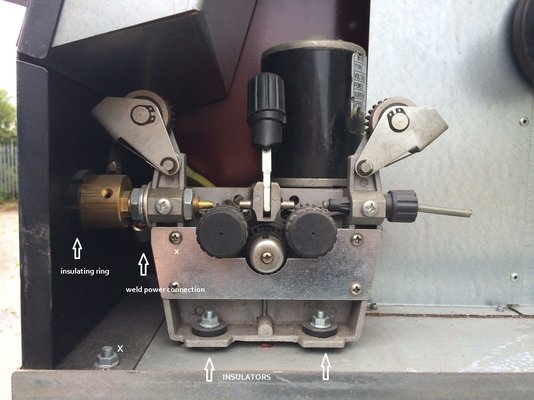

A new problem has occurred with my old Butters. When the torch trigger is pulled when welding, the welding wire glows red hot in the machine and sparks fly as the wire holding reel makes contact with the body of the welder. The wire eventually melts. When the trigger is pulled when not welding everything is fine. Is there a short in the torch or the machine? I've had a quick look and can't see anything obvious. I've cleaned the shroud and tip on the gun and checked for loose wires.

There seems to be continuity between the earth terminal on the torch connector block and the wire feed-in on the back of the block. Is this normal? There are two live pins on the connector. These show continuity when the trigger is pulled. I assume this is normal.

Help!

Many thanks!!!

A new problem has occurred with my old Butters. When the torch trigger is pulled when welding, the welding wire glows red hot in the machine and sparks fly as the wire holding reel makes contact with the body of the welder. The wire eventually melts. When the trigger is pulled when not welding everything is fine. Is there a short in the torch or the machine? I've had a quick look and can't see anything obvious. I've cleaned the shroud and tip on the gun and checked for loose wires.

There seems to be continuity between the earth terminal on the torch connector block and the wire feed-in on the back of the block. Is this normal? There are two live pins on the connector. These show continuity when the trigger is pulled. I assume this is normal.

Help!

Many thanks!!!