T.E.D. Jordan

Member

- Messages

- 63

Hi,

any help would be appreciated!

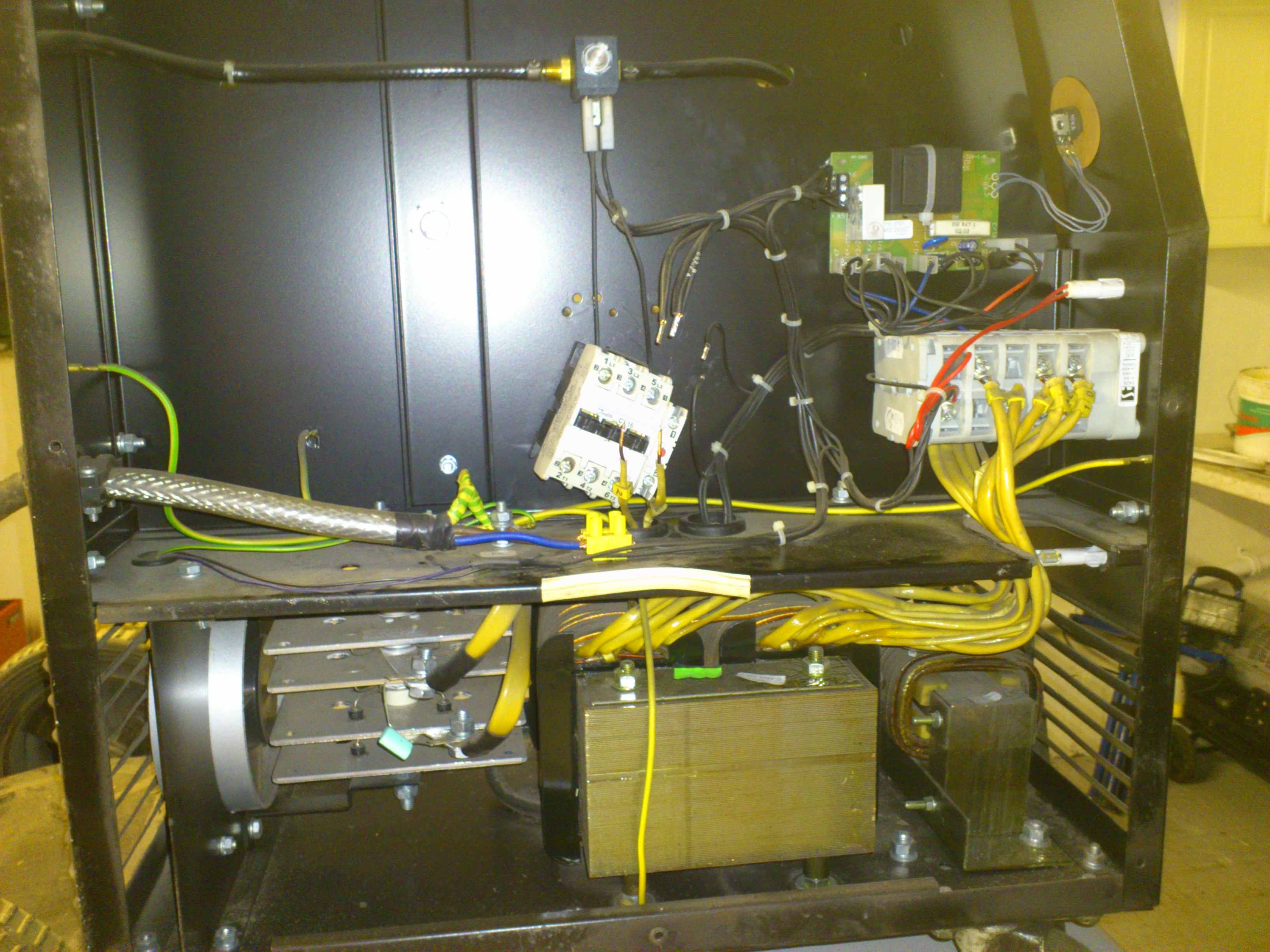

I bought a Lincoln Electric Compact 220 mig welder for pennies recently, as 'condition unknown' (Basically I was under no illusion to the fact that the welder was not working).

I got it home, wired a 32amp 240V socket in and connected some loose wires to their apparent homes inside the casing. I borrowed a euro trigger off another welder from round the corner and put a new cable on the machine.

When turned on, the light comes on, it makes the right noise for idling (Fan spinning at the back etc), but when I press the trigger the motor for the wire feed does not turn and it barks a flat noise back, and I can see some plastic unit pulling what appear to be relays of some sort in? I've checked the motor off the machine with a 12v DC feed and its perfect so any other ideas?

After a couple of seconds of holding the trigger in it trips my breaker box also.

Any help would be appreciated. Pics to follow.

Jordan

any help would be appreciated!

I bought a Lincoln Electric Compact 220 mig welder for pennies recently, as 'condition unknown' (Basically I was under no illusion to the fact that the welder was not working).

I got it home, wired a 32amp 240V socket in and connected some loose wires to their apparent homes inside the casing. I borrowed a euro trigger off another welder from round the corner and put a new cable on the machine.

When turned on, the light comes on, it makes the right noise for idling (Fan spinning at the back etc), but when I press the trigger the motor for the wire feed does not turn and it barks a flat noise back, and I can see some plastic unit pulling what appear to be relays of some sort in? I've checked the motor off the machine with a 12v DC feed and its perfect so any other ideas?

After a couple of seconds of holding the trigger in it trips my breaker box also.

Any help would be appreciated. Pics to follow.

Jordan