God mode restorations

Member

- Messages

- 8,098

- Location

- uk colchester

Morning guys.

Thought I would start a thread about how I clean my machinery parts and the tools involved. Some of you would of seen my shaper refurbishing on the forum. This is one part of the cube I am cleaning up so thought I'd share.

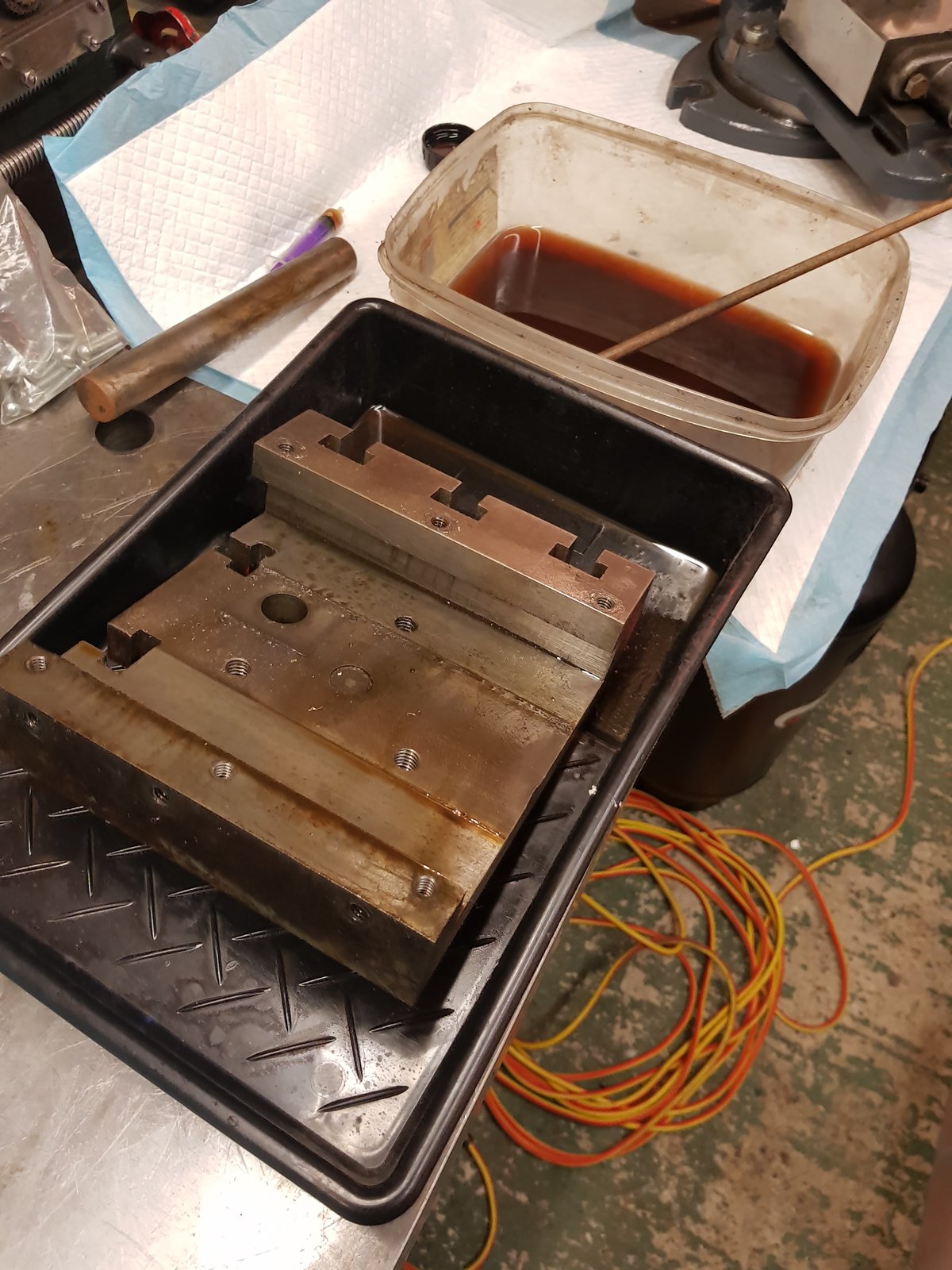

Ok. First picture is the part in a tray. I use gunk to remove oil and grime. The gunk will remove some crud but not all. I use a small paint brush to apply and a scraper to shift stubborn bits.

Thought I would start a thread about how I clean my machinery parts and the tools involved. Some of you would of seen my shaper refurbishing on the forum. This is one part of the cube I am cleaning up so thought I'd share.

Ok. First picture is the part in a tray. I use gunk to remove oil and grime. The gunk will remove some crud but not all. I use a small paint brush to apply and a scraper to shift stubborn bits.

Thank you for the very comprehensive write up.

Thank you for the very comprehensive write up.