andy82

Member

- Messages

- 162

Hi, not posted in here for a while

My work has just ordered me a new tig

Fusion PHF

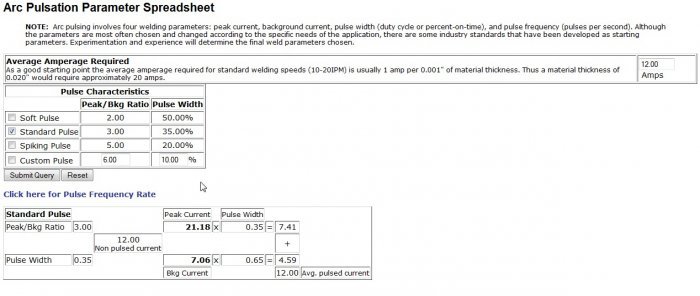

First one with a pulse function, having never used pulse mode on a tig could anyone tell me what the best setting for doing 2 inch exhaust tubing (stainless) would be, the wall thickness is 1.5mm - 2mm.

Just an average setting is needed to try it out until i get used to the machine and play about with the settings.

Another question is there a bigger advantage using pulse on this kind of tubing.

I am doing this sort of thing

My work has just ordered me a new tig

Fusion PHF

First one with a pulse function, having never used pulse mode on a tig could anyone tell me what the best setting for doing 2 inch exhaust tubing (stainless) would be, the wall thickness is 1.5mm - 2mm.

Just an average setting is needed to try it out until i get used to the machine and play about with the settings.

Another question is there a bigger advantage using pulse on this kind of tubing.

I am doing this sort of thing