Richard.

Member

- Messages

- 18,347

- Location

- Cambridgeshire

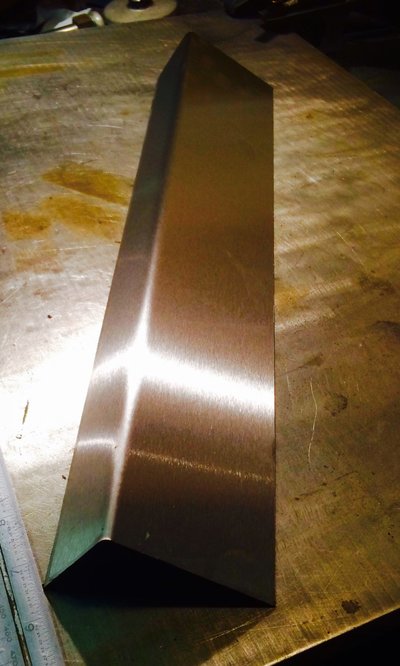

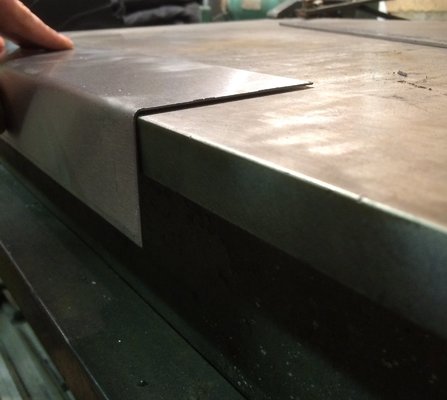

Originally built this in my apprentice days and it's had a few subtle changes over the years. I've got a few 1.5mm SS folds to make in a couple weeks and mine is good for 1mm across its 600mm length. Any thicker and we get bar bow (if such a term exists) any way it got a bit of reinforcement from some 12mm bar off cuts which has achieved my goal. It sharply bends 1.5mm ss now.

It looks a knocked up pile of scrap and it always has done. I could spend time making a real nice job of one but this produces such nice bends I'll keep it for another 20 years.

I even got some nice folds out of some 4mm Alu. Something it wouldn't get close to before.

It looks a knocked up pile of scrap and it always has done. I could spend time making a real nice job of one but this produces such nice bends I'll keep it for another 20 years.

I even got some nice folds out of some 4mm Alu. Something it wouldn't get close to before.