Here's something I've been working on with my friend.

heres a few pics of the kit being made.

making a temporary jig to hold the turbo where we want it.

20 hours later and the manifold, dp, exh system, boost piping is done. i did take pics of the process inbetween, but thought i'd load the best pics.

heres some pics of the turbo kit on a mock engine we had lying around.

we ran out of straight sch10, and had to make do just to get the manifold complete, but the long section on no4 will be gettin replaced.

heres pics of the turbo brace/manifold support

another triangular gusset will be added for further support.

the collector clears the bonnet/hood with about 10mm to spare. an oil filter relocator will be needed with this kit.

best of all, a 4 inch d/p will fit aswell, but the customer specified a 3 inch dp and exh.

the turbo hangs 7mm from the chassis cross beam, and theres lots of space for the wastegate.

best of all, there are only 2 boost pipes, suprisingly, you can manoeuvre the boost pipes into place, even though they are such long weird shape pieces.

material used:

sch10 3mm for the manifold

cnc milled 12mm stainless turbo and manifold flange

2.5 inch stainless hot side boost piping

2.5-3 inch stainless cone and 3inch cold side boost piping

3 inch stainless dp and exhaust.

6mm stainless turbo brace.

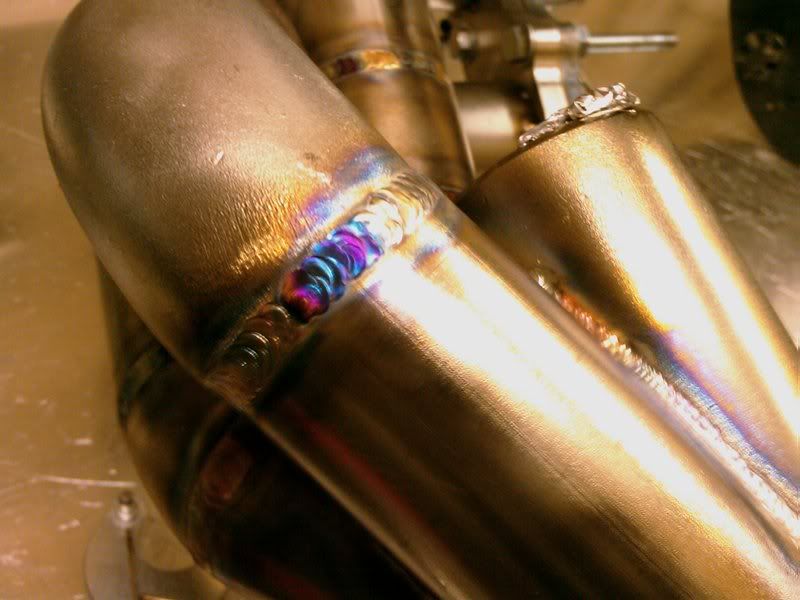

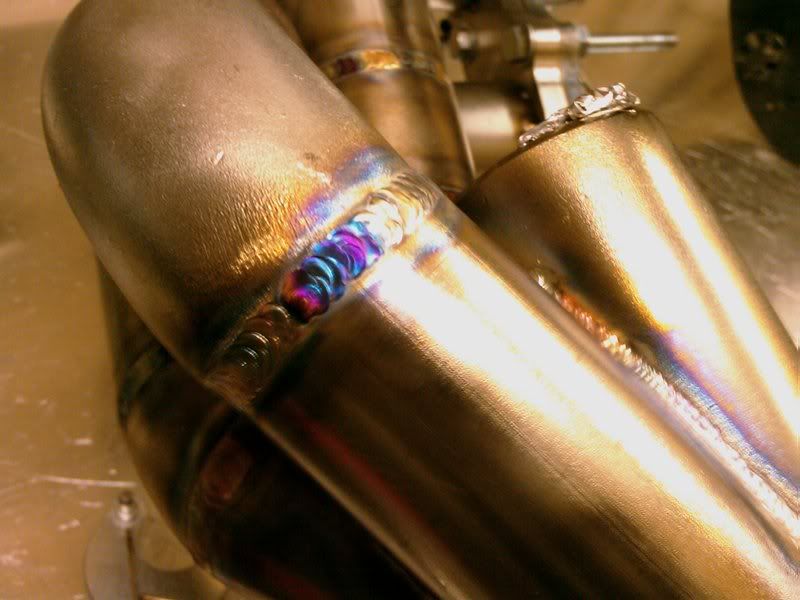

all TIG welded, and manifold will be back purged.

Pic of the JIG

Root pass

Flange welded up

Downpipe flange

Welding the elbow onto the collector. Back purged of course.

Welding the inside of the of the T3 flange.

One runner welded up. Thought it would be best to start with runner 3 first.

Second runner welded up.

Third runner welded up.

Sorry for the bad quality pics. Just have a phone camera on me.

Thanks for looking.

heres a few pics of the kit being made.

making a temporary jig to hold the turbo where we want it.

20 hours later and the manifold, dp, exh system, boost piping is done. i did take pics of the process inbetween, but thought i'd load the best pics.

heres some pics of the turbo kit on a mock engine we had lying around.

we ran out of straight sch10, and had to make do just to get the manifold complete, but the long section on no4 will be gettin replaced.

heres pics of the turbo brace/manifold support

another triangular gusset will be added for further support.

the collector clears the bonnet/hood with about 10mm to spare. an oil filter relocator will be needed with this kit.

best of all, a 4 inch d/p will fit aswell, but the customer specified a 3 inch dp and exh.

the turbo hangs 7mm from the chassis cross beam, and theres lots of space for the wastegate.

best of all, there are only 2 boost pipes, suprisingly, you can manoeuvre the boost pipes into place, even though they are such long weird shape pieces.

material used:

sch10 3mm for the manifold

cnc milled 12mm stainless turbo and manifold flange

2.5 inch stainless hot side boost piping

2.5-3 inch stainless cone and 3inch cold side boost piping

3 inch stainless dp and exhaust.

6mm stainless turbo brace.

all TIG welded, and manifold will be back purged.

Pic of the JIG

Root pass

Flange welded up

Downpipe flange

Welding the elbow onto the collector. Back purged of course.

Welding the inside of the of the T3 flange.

One runner welded up. Thought it would be best to start with runner 3 first.

Second runner welded up.

Third runner welded up.

Sorry for the bad quality pics. Just have a phone camera on me.

Thanks for looking.